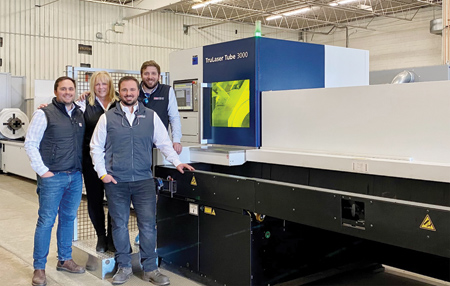

Jack Callender, President, Caltech Manufacturing, along with his mother and two brothers standing next to his TRUMPF TruLaser Tube 3000.

Bucks County, PA, job shop, Caltech Manufacturing, has purchased a TRUMPF TruLaser Tube 3000 from Mid Atlantic Machinery to support the rapid growth of the company. "It is the first non-OEM business to introduce the tube processing capabilities in the county," said a spokesperson.

"This is the final touch to our shop," explained President Jack Callender. "The Tube Laser is taking pressure from our milling and sawing department so that we can better serve customers. The TruLaser Tube allows us to operate as a fully integrated, turnkey solution for the customers we work with."

Caltech Manufacturing, which began as a machine shop and expanded into a fabrication shop, began adding TRUMPF machinery to the floor in 2020 with a 4kW TruLaser, and later a TruBend Press Brakes. The woman and family-owned company offers customers milling, multi-axis turning, press brake bending, flat laser cutting and welding and assembly processes.

"We love to make stuff," explained Callender. "The TruLaser Tube 3000 has improved our efficiency so we can make more parts at a much quicker pace. With the in-house engineering offered at Caltech, our engineers can convert previous processes to a tube efficient process by using the TRUMPF software to manipulate the part without changing it."

Caltech's customer base required a tube process that could be completed in house rather than subcontracting the parts out, allowing Caltech to increase the production speed for its customers.

As an aggressively growing company, Caltech is pushing to work with new customers of a different size. "We have been able to double in size," stated Callender. "We plan to start working with larger companies and expanding even further. The entire Caltech family is excited to build new customer relationships and to embrace the new opportunities we will have because of our new TRUMPF equipment."

For more information contact:

Mid Atlantic Machinery

717-541-1633

www.midatlanticmachinery.com

Caltech Manufacturing Inc.

109 Industrial Drive

Ivyland, PA 18974

215-322-2025

www.caltech-manufacturing.com