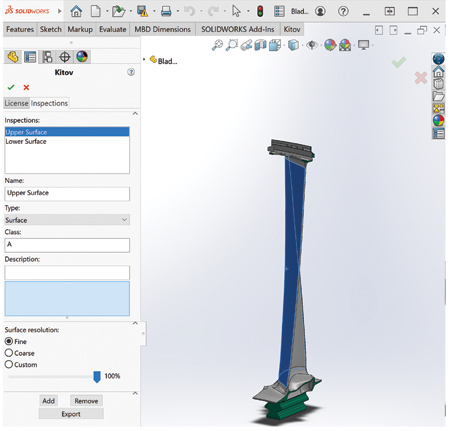

Select inspection requirements using SolidWorks CAD software

Automatically generate an inspection plan from the CAD model

Kitov.ai reported that it has simplified the set-up of robotic vision inspection systems with CAD2SCAN, a CAD-based automated inspection planning tool.

CAD2SCAN is the latest feature of the Kitov Smart Planner. "By combining CAD2SCAN with Kitov's smart visual inspection and Review Station, customers can automate inspection solutions that are too difficult and time-consuming to manually program and deploy," said a company spokesperson.

"CAD2SCAN represents a leap forward in the planning of visual inspection, especially for parts with complex 3D geometry and intricate inspection requirements," explained Dr. Yossi Rubner, founder and CTO of Kitov.ai. "Allowing quality managers to define their inspection requirements directly on the part CAD model, simply and intuitively, will save weeks or even months compared to defining such inspection manually. Our software automatically takes all available information from the CAD, including geometric and component specifications, and uses it for the planning of the robot inspection."

Rubner added, "The inspection plan is optimized in the sense that it fulfills the requirements, guarantees full coverage, reduces the number of images needed, minimizes the total inspection time and calculates the best viewing and illumination angles for each specific feature of interest. In addition, the planner captures multiple inspection points in a single image when possible, reducing the cycle time."

Semantic information extracted from the CAD is passed on to Kitov semantic detectors, which use the information for better inspection. For example, in surface inspection, information on material properties, such as surface reflectance, is used to determine the best illumination angles. Information on screw type and dimensions can enhance screw inspection. Other Kitov semantic detectors, such as labels, barcodes and connectors, benefit from the relevant semantic information extracted from the CAD model.

"Automatic CAD-based inspection planning is a game-changer for industries that manufacture complex parts and products," said the spokesperson. "For example, CAD2SCAN technology improves the inspection of single-material parts with complex 3D geometric shapes, such as turbine engines, blades, wheels and metal molding; CNC parts, where it is very hard and time-consuming to carry out full inspection manually; and custom-made or other low-volume parts (such as medical implants or 3D-printed parts), where it is difficult and not economical to automate inspection in any other way.

CAD2SCAN technology is implemented as a plug-in to common CAD software systems (currently available for SolidWorks and Creo). It also supports the evolving quality information framework (QIF) ISO standard and can parse visual inspection requirements embedded into it.

For more information contact:

Corey Merchant

VP, Americas

Kitov Inc. USA

6937 Village Pkwy., #2151

Dublin CA 94568

925-699-6489

corey.merchant@kitov.ai

www.kitov.ai