GEN MILL T500

GEN MILL 5127

GEN MILL 4024

GEN MILL 2416

GEN MILL 5X-12

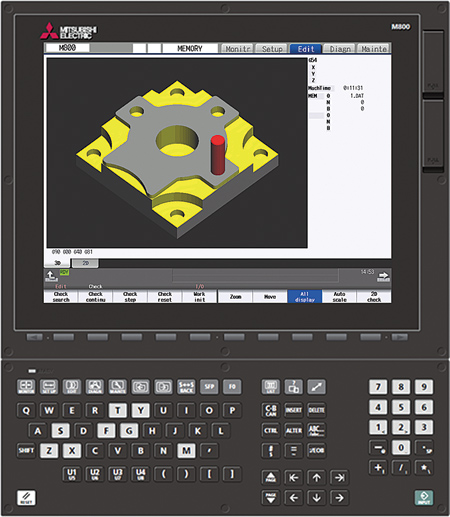

GEN MILL Mitsubishi control

Unified Manufacturing, Inc. specializes in the design and fabrication of CNC machined parts, fixtures and assemblies for various industries.

"While our primary target markets were originally medical and aerospace, we soon found ourselves in many other industries and expanding," said Brian Zimmerman, President, Unified Manufacturing, Inc. "As a job shop, we needed versatile equipment with a small footprint and reasonable price point. We did not know what the next job would be in terms of quantity, material, tolerance and lead time, so the more ground we could cover while maintaining accuracy the better off we knew we would be."

Zimmerman noted that they wanted to focus on making parts by working with their equipment, not on it, and decided to purchase new equipment. "As a new shop, we did not have the cashflow to absorb any major unforeseen repairs, so a warranty was important while getting off the ground," he said. "We wanted to start with a 3-axis machine in order to start building our customer base."

Unified Manufacturing purchased its first VMC, the GEN MILL 2818, from Expand Machinery. "The major selling point for us was the fact that most add-ons were included at about the same price point as the competition-things like a chip conveyor, coolant through the spindle, high-speed machining and a fully unlocked Mitsubishi control," said Zimmerman. "Expand also included a two-year warranty on the machine and three years on the control, which added increased peace of mind for our new business."

The VMC's accuracy and included options allowed Unified Manufacturing to win jobs that the company would have otherwise not been able to bid on. Of particular importance to the company were coolant through the spindle and high-speed look-ahead with nano smoothing. Unified uses coolant through the spindle to flush chips from deep pockets as well as aid in deep hole drilling. Look-ahead capability has been effective in moldmaking applications and 3D surface contouring.

"Due to reduced cycle times and significantly improved surface finishes, we were able to be competitive in moldmaking-a market we originally had no intention of pursuing," said Zimmerman.

The 12,000 RPM spindle has been particularly beneficial. "Had it been a significant upgrade cost, we would have not opted for it-and as a result would not have been able to work on many of the small medical tooling assemblies we manufacture," said Zimmerman.

Additional highlights of the GEN MILL 2818 high-speed 3-axis VMC:

- 24-tool high-speed double arm ATC

- 1,417 IPM rapids

- Spindle chiller for consistent thermal stability

- 2,700 block look-ahead

- 4th and 5th axis wiring

- XYZ axis travels: 27.95" x 17.716" x 18.11".

"In 2014 we started the company with a single GEN MILL machine, a used endmill and a lot of late hours since we had full time jobs at the time," said Zimmerman. "By partnering with another very skilled machinist, Curtis Rolland, VP of Operations, today we have a total of 10 CNC machines from Expand Machinery, including a lathe and a 5-axis machine. We have also purchased a few manual machines from them as well, for a total of 14 machines. We are very happy with this selection, which has enabled us to grow the business."

Unified's machine tool lineup includes:

- GEN MILL T-500 and T-700 high-speed mill/drill/tap centers featuring 12,000 RPM inline direct-drive beltless spindle; 21-tool drum turret; 6,000 RPM synchronous rigid tapping; and 2,362 IPM rapids.

- GEN MILL 5X-12 high-speed VMC with built-in 12" trunnion with glass scale feedback on all 5 axes; roller bearing ways; 54-tool double arm ATC; 1,417 IPM rapids; 12,000 RPM double-ground BIG-PLUS spindle; and spindle chiller. It is available as 4+1 or 5-axis simultaneous. XYZ travels are 34.64" x 32.62" x 25.59".

- GEN MILL 5127 3-axis high-speed VMC with 30-tool high-speed double arm ATC; spindle chiller; 12,000 RPM double-ground BIG-PLUS spindle; 300 PSI through-tool coolant; 2,700 block look-ahead; and 4th and 5th axis wiring. XYZ travels are 51.27" x 27.56" x 25.59".

- GEN MILL 2416 3-axis high-speed VMC with 24-tool high-speed double arm ATC; 1,417 IPM rapids; spindle chiller; 12,000 RPM double-ground BIG-PLUS spindle; 2,700 block look-ahead; and 4th and 5th axis wiring. XYZ axis travels are 24.01" x 15.75" x 17.72".

Unified Manufacturing serves a diverse range of customers and industries. Products manufactured include aerospace parts and tooling, implantable medical device tooling, battery components and waveguide components. Zimmerman said that the company remains competitive by bidding on production work that can be batched and run while lightly monitored, allowing them to concentrate the bulk of their attention on one-offs and more complex assemblies.

"We work closely with the design engineers to help improve manufacturability, and ultimately the desired fit and function they are looking to achieve in order to solve the current matter at hand," said Zimmerman.

For more information contact:

Brian Zimmerman, President

Unified Manufacturing, Inc.

28130 Ave Crocker, Unit 312

Valencia, CA 91355

661-505-8271

unifiedmfg@gmail.com

www.unifiedmfg.com

Expand Machinery LLC

20869 Plummer St.

Chatsworth, CA 91311

888-542-6374/ 818-349-9166

sales@expandmachinery.com

www.expandmachinery.com