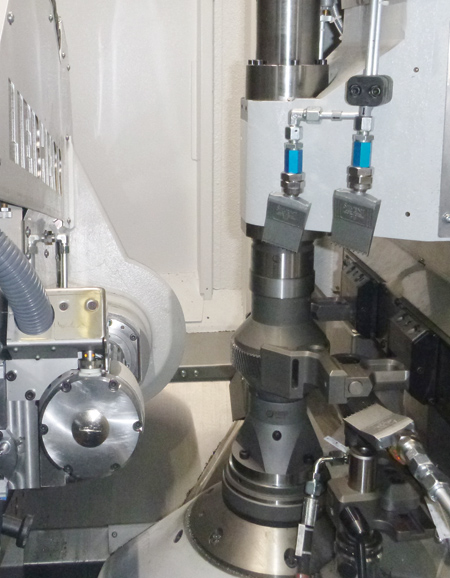

Gear hobbing: Single-cut strategy for larger modules as well, thanks to high clamping force

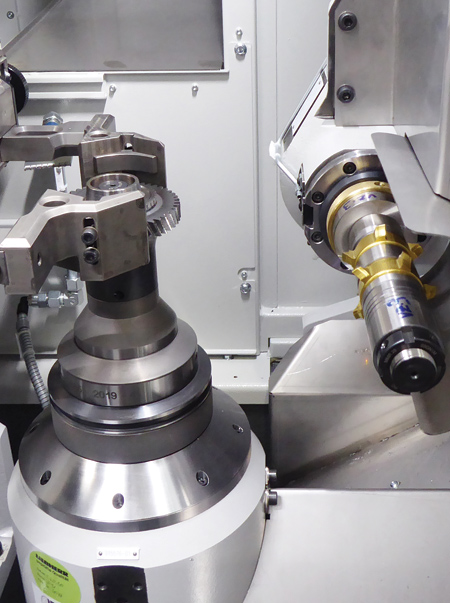

ChamferCut: Also suitable for use with interfering contours

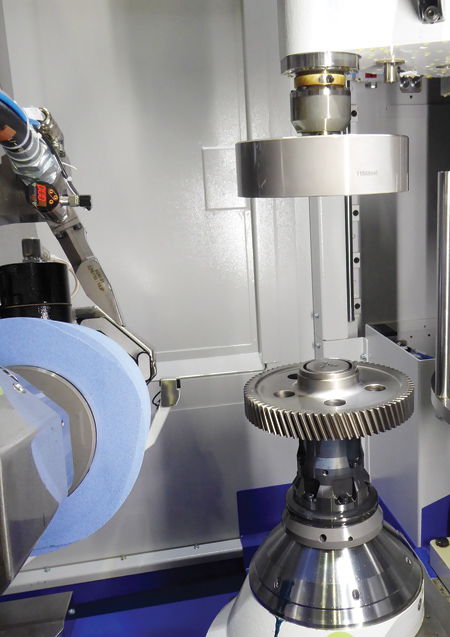

Generating grinding: Frequently used clamping solution for generating grinding

SECLA clamping arbor

The SECLA clamping arbor from Liebherr has been used in its own gear cutting machines for many years. Liebherr also provides after-sales service on the SECLA.

Customer feedback was so positive that, in 2019, Liebherr decided to offer its clamping fixture as a separately available component. The clamping arbor manufactured by Liebherr is designed with modular construction, which enables a clamping fixture exchange in next to no time.

"As well as its diverse variety and its robustness making it suitable for different workpieces, the SECLA also has quick availability," said a company spokesperson. A complete clamping device can be delivered within 10 weeks, while individual components such as the clamping arbor, clamping base and the mounting for the counter column are in stock and thus immediately available.

Liebherr also provides customers with the interface geometry of individual, workpiece-touching components, such as the workpiece support, the centering tip or the clamping top.

Liebherr offers a special peripheral service for the clamping fixture: in case of possible interfering contours, Liebherr conducts advance collision monitoring in the work area as an engineering service. This ensures that production can start immediately after installing the clamping device.

Liebherr has set up a help desk for any questions concerning SECLA. The employees can be reached by telephone or email and will answer any questions about technology, delivery times, commercial handling or will connect you with the right person.

For more information contact:

Liebherr Gear Technology, Inc.

1465 Woodland Drive

Saline, MI 48176-1259

734-429-7225

info.lgt@liebherr.com

www.liebherr.com