The newly developed LASERTEC 100 PowerDrill and LASERTEC 160 PowerDrill are designed for the production of cooling air holes in turbine parts for the aerospace and industrial gas turbine (IGT) sector.

Depending on the application, the LASERTEC 100/160 PowerDrill is available with fiber lasers from 9 kW to 23 kW as well as a PowerShape machine version for shaped-hole processing.

In conjunction with the newly developed laser control system, the LASERTEC 100/160 PowerDrill can produce up to 500 holes per second.

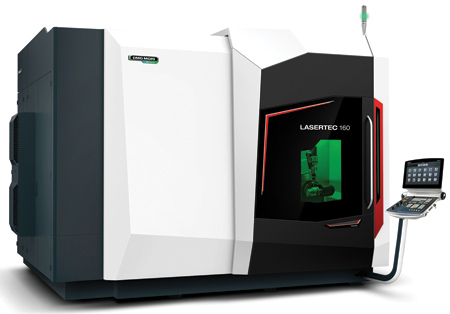

With the models of the LASERTEC PowerDrill series, DMG MORI has a solution to produce cooling air holes in turbine components in the aerospace and industrial gas turbine (IGT) sector. The newly developed LASERTEC 100 PowerDrill and LASERTEC 160 PowerDrill mark a new milestone in this portfolio. While the two large LASERTEC PowerDrill models now feature extended traverse paths, DMG MORI has reduced their footprint. A new moving column concept and a space-saving fiber laser are the highlights of the two world premieres.

Since limited production space has a decisive influence on a company's manufacturing capacity, DMG MORI has developed the new LASERTEC 100/160 PowerDrill for an optimal ratio between installation area and workspace size. The LASERTEC 100/160 PowerDrill offers new features in 5-axis laser drilling. The new, modular moving column concept replaces the LASERTEC 80/130 PowerDrill and is designed for rigidity in the entire working area. Larger travels in X/Y/Z up to 1,600 x 1,000 x 1,000 mm with simultaneously reduced footprint (12.7 square meters / 14.7 square meters) offer maximum flexibility on the store floor.

The modular axis concept, with swivel axis in the tool and rotary axis in the workpiece or alternatively with swivel rotary axis in the workpiece, offer improved kinematics for every application-especially in bucket and combustor machining. Depending on the application, the machines are available with 9 kW to 23 kW fiber lasers as well as the PowerShape machine version for shaped-hole machining. Linear drives in the X and Y axes also provide high dynamics with an acceleration of 7 m/s2 and rapid traverse of up to 90 m/min.

To meet the increasingly high accuracy requirements in the target industries, the LASERTEC 100/160 PowerDrill is based on a new moving column concept with movable X and Y axes. As a result, users benefit from constant rigidity throughout the entire working area. With variable collimation, the laser's focus size can be changed during processing without manual intervention. The LASERTEC 100/160 PowerDrill can be equipped with different fiber lasers depending on the application. In combination with the newly developed laser control, up to 500 drill holes per second can be produced.

The machine concept is designed for laser drilling of components installed in aircraft engines, including turbine guide vanes and rotor blades as well as heat shields, combustion chambers and similar components. The Lasersoft PowerDrill software, which was developed in-house, supports these tasks with a high level of user-friendliness and easy programming.

The LASERTEC 100/160 PowerDrill is engineered with state-of-the-art components, including variable collimation, shot-through detection and a camera integrated into the laser optics. Other features such as capacitive distance sensors or an optional tool changer for different processing heads round off the range.

DMG MORI's CELOS as well as the powerful and user-friendly CNC control SIEMENS 840D solutionline ensure maximum ease of use and process reliability for laser drilling of turbine components. All available LASERSOFT PowerDrill packages combine high-tech performance and are designed for application-oriented, simple programming and operation.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com