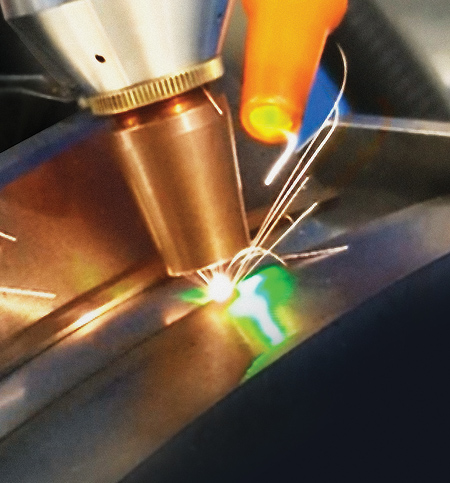

The LASERDYNE 890 fiber laser system is designed for large part welding, drilling and cutting.

The latest generation of BeamDirector technology provides crash protection in a compact profile that allows drilling at angles as shallow as 10° from the surface throughout the entire work envelope.

SmartShield provides protection against excessive oxidation in the weld area while also protecting the beam delivery optics with regular, clean shop compressed air.

"Prima Power has introduced the LASERDYNE 890 system with powerful and efficient fiber laser, the latest highly flexible BeamDirector and the S94P control loaded with a full portfolio of Smart Techniques operating capabilities," said a company spokesperson.

Featuring a large 96" x 72" x 36" (2,440 mm x 1,830 mm x 400 mm) work envelope for the X, Y, and Z axes-along with the latest BeamDirector and a complete flexible 5-axis work envelope-the modern LASERDYNE 890 is designed for today's challenging large part welding, drilling and cutting processes. Its spacious gantry design configuration has proven useful in fixturing large and complex parts, allowing for faster and more efficient high-value part set-up and laser processing.

"With enhanced performance and efficiency, the fiber lasers provide consistent pulse power and energy stability," said the spokesperson. "The QCW fiber laser delivers maximum peak power equal to 10x that of average power. The S94P controller delivers precise and controlled pulses for consistent and reliable manufacturing processing. The fiber lasers are more efficient and provide significant cost savings over CO2 and Nd:YAG lasers. Migrating to a fiber laser source eliminates the need for helium gas requirement and lowers the operating cost."

The LASERDYNE 890 includes the latest generation of the BeamDirector. It provides rotary and tilt (fourth and fifth) axes of laser beam motion. Rotary (C-axis) motion is 900° about the vertical axis while tilt (D-axis) travel is ±150° about the horizontal axis.

The Prima Power Laserdyne BeamDirector features direct drive design, optical encoders for high accuracy (±15 arc-second) and repeatable, high assist gas pressure and flow, and adjustable mirrors for easy and accurate beam alignment. The high capacity direct drive design eliminates gears and belts for higher accuracy, allowing greater travel and reach over zero offset style wrists.

The Prima Power Laserdyne S94P control includes smart solutions for welding, drilling and cutting of clean accurately produced parts in a broad range of standard or specialty materials including the latest high temperature and exotic metals. The S94P control capabilities include:

- Automatic Focus Control for capacitive part sensing (uncoated metals) creating unlimited R-axis correction with speed and enhanced sensitivity

- Optical Focus Control (OFC2) for sensing and mapping of thermal barrier (ceramic) coated surfaces

- CylPerf and ShapeSoft graphical programming utilities for producing patterns of cylindrical and shaped holes

- PresSure for control of assist gas pressure from within a laser processing program

- Adaptive hole size control, designed for producing highest quality laser drilled holes, helps ensure hole size and critical flow requirements with minimal operator involvement

- SPC Data Acquisition monitors and records key processing data used to create each part and records the data in a permanent record

- MTConnect provides real-time streaming of the process parameters in support of IIoT and Industry 4.0.

The LASERDYNE 890 also incorporates an expanding suite of proprietary capabilities, called SmartTechniques, that are standard features of its S94P control. They include:

- SmartShield provides protection against excessive oxidation in the weld area while also protecting the beam delivery optics with regular, clean shop compressed air.

- SmartPierce minimizes spatter and reduces time for piercing in cutting and drilling processes.

- SmartRamp eliminates the depression at the end of laser welds.

The LASERDYNE 890 incorporates a rigid base with heavy-duty steel weldment construction and robust motion system with precision machined surfaces and a reliable motion system.

For more information contact:

Prima Power Laserdyne

7105 Northland Terrace North

Brooklyn Park, MN 55428

763-433-3700

lds.sales@primapower.com

www.primapowerlaserdyne.com