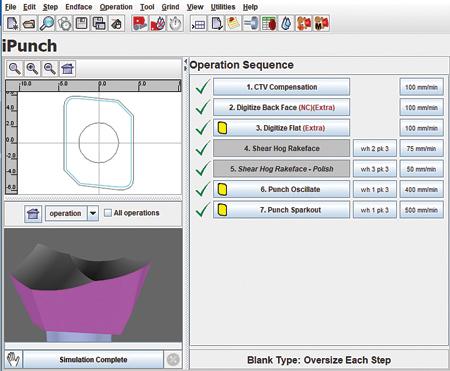

A software interface to allow for the adjustment of specified insert parameters, including corner radius, periphery relief angle and rake face dimensions. Digitizing software verifies the insert orientation prior to grinding.

A modification to the robot gripper head allows the robot to pick up and handle the insert/nail combination. Robot loading software was developed to enable to the machine to pick up the insert and load and unload the nail via an interchange station.

AB Tools, a U.S. based specialist tool manufacturer, requested a solution to manufacture special carbide inserts. They were seeing a growing demand for this product and asked ANCA to supply a solution based on an MX7 Linear for autoloading and grinding special inserts. Existing machinery and processes were not versatile enough for them to successfully meet their demands.

ANCA's engineering team worked to find a solution. The team can custom design mechanical, electrical, software and process solutions to enhance the standard product range and meet unique customer requirements. Simon Richardson, ANCA Product Manager, said, "Developing new technology that directly addresses customers' requirements benefits everyone. Our founders are often heard reflecting that some of our greatest product breakthroughs have originated from custom projects."

Alfred Lyon, AB Tools Shop Supervisor, said, "Both Jon Baker, the President at AB Tools, and I were extremely impressed with the whole process. Starting with our own testing followed by having Simon come scope out our needs and ascertain what we wanted to accomplish, we then flew to Melbourne to meet with the incredible customer solutions team that took our requirements and ran with it. Lastly, and most important, ANCA sent engineers to iron out all last-minute details. Basically, our goals were not merely met but exceeded."

The engineering team was requested a solution that was able to:

- Autoload and grind a range of AB Tools shear hog inserts

- Perform grinding operations in one set-up

- Meet cycle time requirements

The custom solutions engineering team delivered an enhancement to the ANCA MX7 with Robomate. New designs developed included:

- A modification to the loading system with custom pallets to suit the inserts. The custom pallets can hold up to 442 inserts, and this capacity can easily be increased by ordering the four-pallet upgrade option available on the MX7 Robomate.

- A modification to the robot gripper head allows the robot to pick up and handle the insert/nail combination. Robot loading software was developed to enable to the machine to pick up the insert and load and unload the nail via an interchange station.

- Custom anvil nose workholding to clamp the inserts, with the added benefit of a variable force drawbar system. This drawbar allows flexibility to grind different sized inserts and to effectively clamp different sized tooling.

- A software interface to allow for the adjustment of specified insert parameters, including corner radius, periphery relief angle and rake face dimensions. Digitizing software verifies the insert orientation prior to grinding.

The grinding and loading process is running within the customers parameters. Inserts can be ground in a cycle time that currently is less than six minutes.

Lyon concluded, "ANCA impressed me from day one. Creating basically a whole new type of machine for AB Tools is not merely impressive-it is extraordinary. We could have purchased another machine just like the one we were using, but we asked ANCA for help because we wanted to expand our capabilities and simplify our process. This new machine has exceeded both requirements."

For more information contact:

AB Tools, Inc.

1051 Aviation Blvd.

Lincoln, CA 95648

866-440-8665

www.abtoolsinc.com

ANCA Inc.

31129 Century Drive

Wixom, MI 48393

248-926-4466

usainfo@anca.com

www.anca.com