Version 20 offers innovative bevel capabilities such as advanced toolpath generation and rule-based corner transitioning.

Color Offload is a shop floor tool that uses color-coding to track parts by next operation.

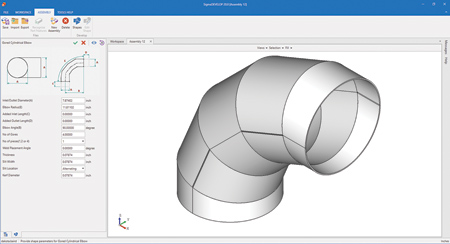

SigmaDEVELOP, a 3D system for standard ducting and HVAC geometry, can convert multi-piece common line gores into a single no-kerf, common line part.

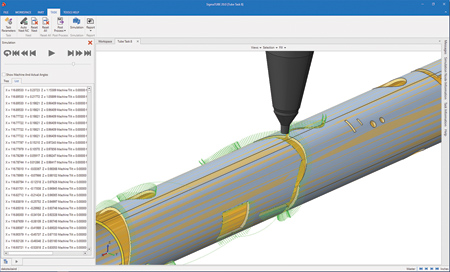

Version 20 of SigmaTUBE includes support for new inventory profiles and tab and notch enhancements.

SigmaTEK Systems, a developer of CAD/CAM software solutions for the fabrication industry, has announced the latest release of its flagship SigmaNEST product portfolio. Version 20 is a substantial release introducing many new features in all areas of the product with continued emphasis on user experience, optimizing material utilization and data management.

A new SigmaTEK Launcher provides a common, customizable desktop platform from which users can easily access core SigmaTEK products and eco-system applications such as license manager, database utilities and help resources. The Launcher also displays a live social media feed to ensure users are fully up to date with the latest product information, trade shows and educational webinar schedules.

SigmaNEST enhancements includes support for part priority nesting, nesting of filler parts and nesting of "mini-sheets" or mini-nests. User efficiency continues to be a focus and a new CAD Import Plus module is available that does not require a local CAD installation to import a variety of file formats, including SOLIDWORKS, Solid Edge, Creo, Inventor and NX. In addition, SigmaNEST 20 adds feature recognition (drilling, partial-depth pockets, bevel) for STEP files.

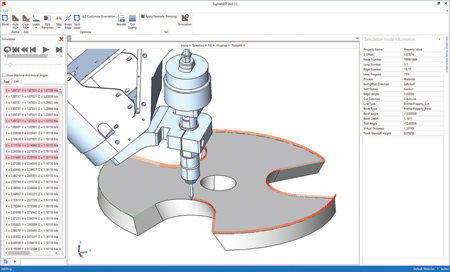

Significant profiling enhancements see the introduction of innovative bevel capabilities such as advanced toolpath generation and rule-based corner transitioning. Users now can import part files with complex bevels and apply NC directly to the 3D model in an interactive 3D viewer to ensure a safe and accurate toolpath generation and better program verification.

Other SigmaNEST developments include expanded support for the TRUMPF TruMatic 1000 Fiber punch laser machine, laser precutting for creating complex threaded holes on combination machines, and the use of raw sheet edges as the part edge with improved height detection and probe cycles near the sheet edge.

The challenge of delivering an accurate quote is fundamental to the success of a project. Version 20 delivers SigmaQUOTE, a new integrated job quoting tool that replaces SigmaNEST's previous Jobs module. It is powered by SigmaMRP, so it leverages the product's quoting functionality, allowing users to manage companies and contacts, generate quotes for new projects, and turn quotes into work orders for production within SigmaNEST.

Further improvements to the SigmaTEK 3D suite of applications for tube, bar stock, 3D models and sheet metal forming include the ability to convert multi-piece common line gores into a single no-kerf, common line part within SigmaDEVELOP, a 3D system for standard ducting and HVAC geometry. SigmaUNFOLD flattens the 3D patterns and allows them to be manipulated for cutting and bending operations. An automatic slit-creation option adds a slit to an otherwise solid part so it can be unfolded into a flat pattern that can be processed on either cutting or press brake machines.

For SigmaBEND, version 20 includes a new radial menu with dynamic shortcuts for editing the tool stations, backgauges and the part itself, as well as improved sequencing and backgauge options. A new manual station-generation tool allows for easy manual tooling set-up. SigmaTUBE generates nests and NC code for tube and pipe cutting on laser and plasma machines, and Version 20 includes support for new inventory profiles and tab and notch enhancements.

SigmaTEK also develops applications that drive the continuous workflow of data throughout the shopfloor. Version 20 delivers updates to Color Offload, a tool that uses color-coding to track parts by next operation, with the ability to filter by program status as well as document management capability. SimTrans is a transaction manager that links SigmaNEST with other business systems. Users can leverage SimTrans automation to create or load parts, manipulate orders or update inventory in real time. Version 20 adds new transactions for managing jobs and provides the ability to receive email notifications for regular status updates or invalid parts.

For more information contact:

SigmaTEK Systems, LLC

1445 Kemper Meadow Drive

Cincinnati, OH 45240

513-674-0005

info@sigmanest.com

www.sigmanest.com