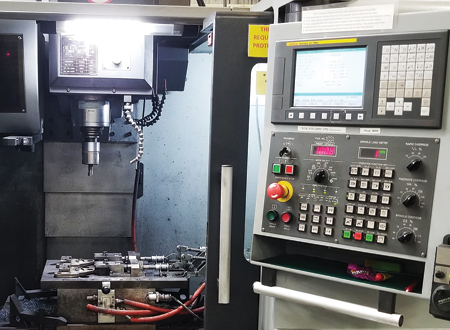

Kent VMCs at Miyama USA. Miyama USA's 50 employees serve a variety of automotive and appliance customers, with capabilities that include stamping, machining, robotic welding and precision assembly.

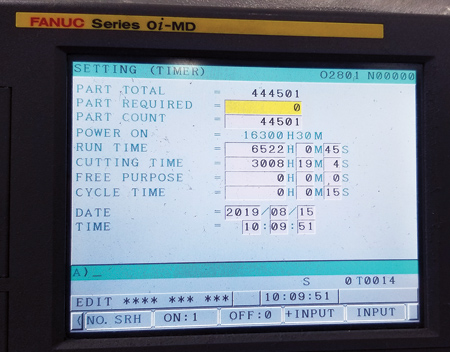

Note the PART TOTAL and POWER ON counters on Miyama USA's KVR-2418 VMC from Kent Industrial

For four years now, each of the KVR-2418 VMCs at Miyama USA produces two seat gears every 35 seconds, with three tool changes per cycle.

Being a Tier 3 supplier to automotive and appliance OEMs is high-volume, extremely competitive work, where success depends in large part on fast, accurate and above all dependable equipment. Fortunately for Bill Overbay, manufacturing supervisor at Miyama USA Inc. in Louisville, KY, his latest round of machine tool purchasing gave him exactly that. "We now have five Kent machining centers in all, and most have been running nonstop for the past four years," he said. "We have had no problems whatsoever."

The Solution

After winning the bid nearly five years ago on a long-term contract for an automotive seat gear, Overbay and his team were faced with tooling up for the big job, beginning with the purchase of three new CNC vertical machining centers (VMCs). At first glance, the parts were small enough that a drill-tap machine seemed like it might be a more logical choice, but because each gear required semi-finish and finish boring operations, Overbay knew that a 40-taper machine would be needed to accommodate the adjustable boring heads, each of which weighs close to 4 lbs.

Still, he did not want to sacrifice speed and accuracy. "When you are a Tier 3 supplier, price per part is everything," he said. "This presents a strong argument for finding the least expensive machine available. But we also needed one that was fast enough to meet our cycle time objectives, and able to consistently hold tolerances down to 20 microns (0.0007 in.) on a pair of holes."

After evaluating several well-known brands of equipment, Overbay reached out to Glen Goins, President of Amerigo Machinery Co., whom he had known previously. "Glen has been in this business longer than anyone and I trust him to stand behind his equipment. He will do whatever is needed to treat his customers right," said Overbay. "He showed us a couple different options, but it was the KVR-2418 VMC from Kent that we kept coming back to. Where everyone else makes you pay for a 12,000 RPM chilled spindle upgrade, a better control and other needed machine options, Kent includes those features as standard, and has a lower price."

Running Hard

Despite the price, the KVRs have proven to be extremely reliable. Each of the machines produces two seat gears every 35 seconds, and does so 16 hours a day, five days a week. With three tool changes per cycle, that comes out to nearly 1.5 million tool changes annually. "Aside from the routine maintenance to replace the tool pods every year or so-something that is quite reasonable considering the high number of tool changes-we have had no appreciable downtime, and the only failures are when the operator accidentally stops the machine in the middle of a tool change," said Overbay. "And after four years of moving to the exact same four points, we have almost no visible wear on the ball screws."

Tool life has also been exceptional, according to Overbay. The seat gears are made of 400 series stainless steel that has been heat treated to 62 Rc, hard enough that relatively expensive polycrystalline cubic boron nitride (PCBN) cutting tools are needed. Due to their brittle nature, however, these tools require rigid, stable machining conditions if they are to last as long as possible. Here again the Kent KVR does not disappoint, producing up to 3,000 parts per tool, a figure that Overbay said they are quite proud to achieve.

Looking Forward

Because of this long-standing success, Miyama has since purchased two additional KVRs, bringing the total to four machines dedicated to seat gear production and one for general shop work. In fact, Overbay estimates they have made more than four million of the automotive components so far, with all of the machines still going strong.

"To be honest, I initially thought we were buying an inexpensive machine that would hopefully last long enough to get us through the project. But over the past four years, I have been pleasantly surprised by the quality," he said. "A lot of people think I am joking when I tell them how many tool changes we are doing each year. My response is that the machines are fantastic. The price was significantly lower than competing brands, and they are fast and accurate. Even though we push them very hard each day, they just keep on making parts."

Miyama USA is a wholly owned subsidiary of Miyama Kogyo Co. Ltd. in Japan. Since 1980, it has served a variety of automotive and appliance customers in the U.S., with capabilities that include stamping, machining, robotic welding, assembly and other value-added services. The company and its 50 employees pride themselves on 100% on-time delivery and unerring quality, both necessary attributes in an environment where business is decided on margins of pennies per part.

For more information contact:

Miyama USA

7081 International Drive

Louisville, KY 40258

502-933-4100

www.miyamausa.com

Kent Industrial USA

1231 Edinger Ave.

Tustin, CA 92780

800-KENT-USA / 714-258-8526

sales@kentusa.com

www.kentusa.com