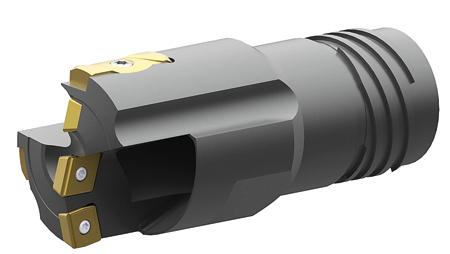

Sunnen DirectDex Drill Head

DirectDex Guidepads

DirectDex Inserts

Sunnen Products Company offers a series of drill heads, inserts and pads that are directly interchangeable with Sandvik deep-hole drilling tools. The line, Sunnen DirectDex, features BTA/STS (Single Tube System) and DTS/Ejector (Double Tube System) style deep-hole drilling tools designed to produce a low cost-per-bore with consistent performance. The product series directly corresponds to the previously available line of Sandvik drill heads, inserts and guide pads, with additional product series set to be released.

CVD- and PVD-coated inserts are available in two grades designed for excellent wear resistance and toughness. "The CVD-coated inserts are optimal for machining heat-resistant super alloys and also work well with ISO P, K, H and N materials," said a Sunnen spokesperson. The PVD-coated inserts are specifically designed for ISO P, K, H and N materials, and also provide resistance against built-up edges.

"We are excited to be able to fill the recently created void in the market for Sandvik-style tooling," said Chris Miltenberger, President and COO of Sunnen Products Company. "This is congruent with our strategy to be the one source solution for systems and tooling related to bore machining, whether the process used is deep-hole drilling, skiving/roller burnishing, lapping or honing."

Sunnen's core technical competencies include automated and manual systems, custom system development and integration, abrasives, tooling, cutting fluids and bore gauging. Through acquisition and new product development, Sunnen has expanded from its honing expertise to include tooling for initial hole creation and other complementary bore sizing and finishing processes such as trepanning, counterboring and form boring.

For more information contact:

Sunnen Products Company

7910 Manchester Road

St. Louis, MO 63143

800-325-3670 / 314-781-2100

sales@sunnen.com

www.sunnen.com