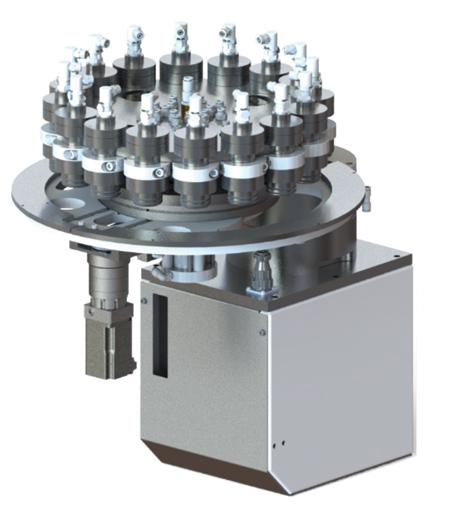

Multi-Hopper Powder Feed System

April 1, 2020

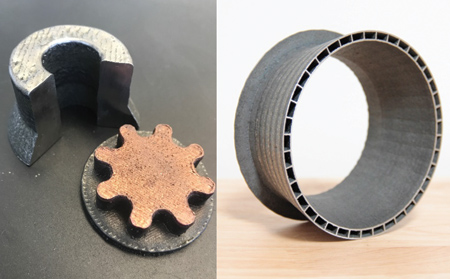

Both simple and complex geometry parts built with gradient and bi-metallic strategies.

FormAlloy Technologies, Inc., a metal additive manufacturing (AM) company, has released the second edition of the multi-hopper powder feeder known as the Alloy Development Feeder (ADF). The 16-hopper Alloy Development Feeder (ADF) modularly interfaces with directed energy deposition (DED) systems to enable deposition of multiple materials in a single build and high throughput bulk alloy synthesis for development of new materials and alloys.

According to material development expert and University of California San Diego Professor Dr. Kenneth Vecchio, "The ADF provides an unprecedented capability for material development and research."

The need for new alloys optimized for AM is not only evident by researchers and materials companies, but for end users as well. In particular, end users of AM in the aerospace and automotive industries are investing in new materials that have superior properties to the traditional materials that were developed for traditional manufacturing processes. By innovating in the alloy development space, FormAlloy is enabling not only researchers, but also the end users by facilitating rapid development of new alloys that can be utilized for product improvement and enhanced material properties for their own products.

In addition to new alloy development, the ADF enables precise deposition of gradient materials. "Fabrication of multi-material structures or functionally graded materials (FGM) can significantly simplify the process chain for multiple-part assemblies and provide enhanced material properties and performance," said a company spokesperson. "Each layer is pre-alloyed to ensure composition accuracy for detailed gradient strategies that are not achievable with other processes." Both simple and complex geometry parts can be built with gradient and bi-metallic strategies. For components such as rocket nozzles, regions with concentrated heat loads can be fabricated out of higher temperature materials while other regions can be fabricated out of higher strength materials.

For more information contact:

FormAlloy

2830 Via Orange Way Suite H

Spring Valley, CA 91978

619-377-9101

info@formalloy.com

www.formalloy.com

RAPID + TCT 2020 Booth 2430

< back