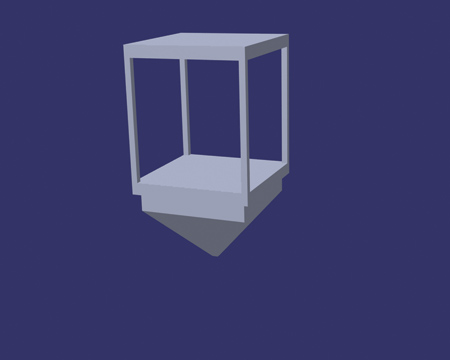

CAD model of the test item (gray) with support structure (green); the support structure is not modeled out, but "only" defined as volume.

CAD model of the test item

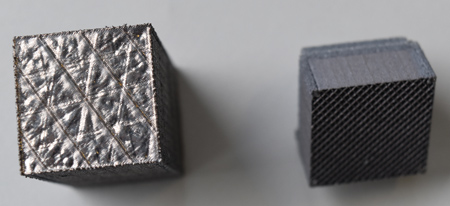

Top view of the printed test item (left), test item sliced open (right)

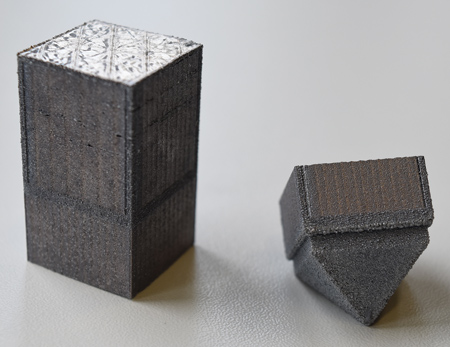

Test items with support structures (left), sliced open test item with partially removed support structures (right)

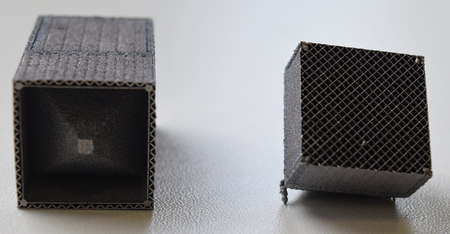

Test item from the bottom (left), top view of the sliced open test item (right). What can be clearly recognized here is the structure that the post-processor generated from the volume.

"The European 'Bionic Aircraft' research project has reached yet another milestone for additive manufacturing (AM): for the first time ever, components can be printed directly from the CATIA V5 CAD system," said a spokesperson. "This is made possible with the interface developed by CENIT. With it, there is no need to leave the development environment. All process steps, including post-processing, can be mapped in CATIA V5. Now, exact data is available in CATIA V5 for removing the support structures during 3D part post-processing-elaborate reconstructions of the model and the support structures are a thing of the past."

Since 2016, the objective of the Bionic Aircraft research project, funded by the European Commission, has been to reduce emissions in the aviation industry. Ten international consortium partners from industry and R&D, including IT specialist CENIT and Fraunhofer Institute for Additive Production Technologies (IAPT), are collaborating to come up with new methods and concepts. In this project, 3D print and bionic design play an important role in efforts to reduce the weight of aircraft components, thus reducing fuel consumption.

"Future users will be able to reduce their time and costs resulting from the closed process chain for AM, because now the development process for a part until series maturity has become significantly leaner," said the spokesperson.

Jochen Michael, Senior Consultant at CENIT, said, "Support structures of additive manufactured components should not be removed manually in series production, but instead with NC machines. When creating NC programs of this type, the STL format, which in the past was used primarily for the representation of component and support structures in the 3D print data chain, is inadequate, because it can only represent the geometry imprecisely. In that case, the model and support structures must be reconstructed for refinishing, resulting in unnecessary expense. We can prevent this with the 3D print from CATIA V5 directly, because the exact geometry data for this post-processing is already available."

In order for the 3D print to be successful via CATIA V5, CENIT provides support to the engineer in the preparation of data from topology optimization. During topology optimization, in a computer-aided process, the material for the component is reduced to the amount that is absolutely necessary to meet the requirements. The CATIA V5 Slicer, newly developed by CENIT, then slices the component into layers. The contours of these slices are sent directly to the 3D printer via the post-processor developed by CENIT.

New Support Structures from Fraunhofer IAPT

Another positive interim result of the Bionic Aircraft project: Fraunhofer IAPT has developed optimized support structures. Support structures provide the needed support to additive manufactured components at certain areas, for example at overhangs, and must be removed after the 3D printing prcess.

"Due to an optimized geometry, the new support structures do not need as much powder," said Melanie Gralow of Fraunhofer IAPT. "We were inspired by nature, which is known for its material efficiency. The hierarchically branched structures, with gradients that were created as a result, reduce powder consumption by 70% - 90% as compared to conventional support structures. This allows us to save material and reduce production costs at the same time. An additional benefit is that they can be removed easier than conventional support structures. This makes post-processing faster, reducing the risk of damage to the component when they are removed."

The optimized structures are set up in CATIA V5 directly.

For more information contact:

CENIT North America, Inc.

691 N. Squirrel Rd., #275

Auburn Hills, MI 48326

248-309-3240

info@cenit.com

www.cenit.com

Bionic Aircraft

www.bionic-aircraft.eu