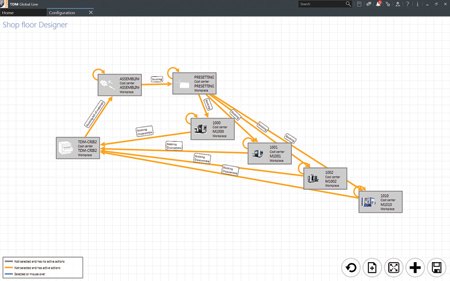

With TDM Shopfloor Manager sensible processes are already created by default in the software.

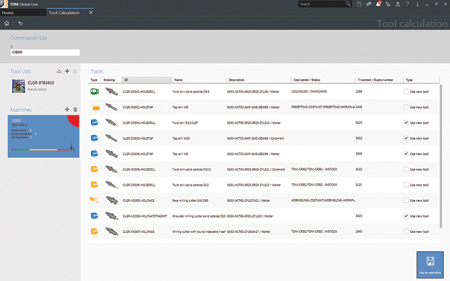

TDM Shopfloor Manager provides clear information about where the tools are used and what their condition is.

TDM Systems, a provider of tool data management systems for industry and software developer in the field of tool management, offers its Shopfloor Management under TDM Global Line. With the TDM Shopfloor Manager, the customer can individually build and illustrate the entire tool workflow on the shop floor.

"The days when a shopfloor had to adapt to rigid software are gone. Consistent and modular in design, the TDM Shopfloor Manager tool adapts to all circumstances in order planning, configuration, as well as workflow for cribs, assembly, presetting, machine and secondary cribs," said Volker Schwegler, Senior Product Manager at TDM Systems.

No matter whether the users are dealing with orders, individual workpieces or NC programs, everything is broken down into tool lists and each person involved in a process can view the precise information required for the specific task.

Schwegler added, "Many companies combine tool assembly and presetting together in one tool room, for example. With TDM Shopfloor Manager, the two areas can be combined to form a cost center and all actions can be combined into a single screen."

"The software is freely configurable, without any need to adapt the programming," said a company spokesperson. "This flexibility also reduces an individual adjustment. At least 80% of user needs can be covered as standard. However, too much flexibility could lead to faults if processes are compiled in the wrong sequence."

TDM Shopfloor Manager is fully compatible with the stock management of the TDM Tool Crib Module Global Line. This means that even tool assemblies in secondary cribs and those near machines can be managed.

For more information contact:

TDM Systems

1901 N. Roselle Rd., Ste. 800

Schaumburg, IL 60195

847-605-1269

info@tdmsystems.com

www.tdmsystems.com