Measurement Software for Enhanced CMM Programming

October 1, 2019

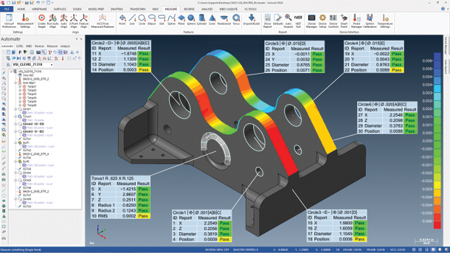

Verisurf 2019 includes a detailed pane and feature ballooning to show real-time deviations of measured features compared to nominal.

Verisurf 2019 is the latest release of the measurement software for automated quality inspection and reporting, scanning and reverse engineering, tool building and assembly guidance. Enhancements in the new release focus on automated inspection and compatibility across the manufacturing enterprise, whether in the quality lab or on the shop floor.

"Verisurf 2019 provides a common inspection and measurement platform for the manufacturing enterprise. It allows users to create a single inspection plan that can be implemented across all measuring devices, regardless of type or brand," said Ernie Husted, President and CEO of Verisurf. Verisurf 2019 can be used to program and operate new and legacy CNC CMMs, and the same inspection routine can also be used with portable arms and trackers. "This universal compatibility provides increased productivity and continuity between first article and production inspection, as well as the flexibility to move between the quality lab and the shop floor," added Husted.

Verisurf 2019 is available in German, Chinese, Italian, Russian, Japanese and Spanish language versions. The software includes added features and enhancements developed as a result of ongoing user feedback.

Highlights include:

- Feature Data Extraction-This new function quickly constructs measured features by extracting data from point clouds created using laser scanners or touch probe devices. The software can identify and extract feature data based on defined CAD nominals or from previously measured features scanned or probed using Teach Mode, which is suitable when a CAD model is not available.

- Details Pane and Feature Balloons-These two new features make it possible to view real-time deviations of a measured feature compared to nominal. The CAD model can be used as the nominal, or if no CAD model is available, nominal specifications can be manually entered using the Details Pane.

- Power Mesh-This is a one-click tool to create, clean up, refine, smooth and close new or existing mesh models from multiple overlapping point clouds generated from measured scan data.

For more information contact:

Verisurf Software, Inc.

4907 E. Landon Dr.

Anaheim, CA 92807

888-713-7201 / 714-970-1683

info@verisurf.com

www.verisurf.com

< back