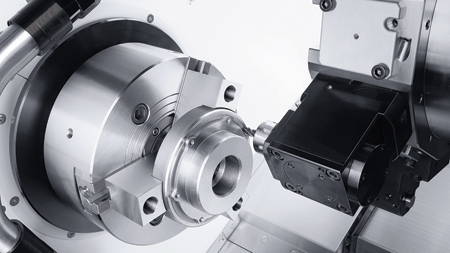

BMT turret with max. 6,000 RPM and max. 11.7 ft-lbs. for machining with driven tools.

The ALX 2500 is engineered to combine performance, precision and process reliability.

DMG MORI offers its ALX 2500, a high-performing turning machine. The ALX 2500 is designed to meet the high demands of serial production in automotive and other demanding industries. The ALX 2500 offers a high degree of automation with an optional gantry loader, along with cost-effective production.

The ALX 2500 features a maximum spindle speed of 3,500 RPM, BMT turret with 12 powered tools and tailstock and an ergonomic design for operation and maintenance within its compact 52.6 sq. ft. footprint.

The sturdy construction of its slideways on the X-axis and linear motion guides on the Z-axis provides increased damping properties and a high level of positioning accuracy. This is of particular benefit in the automotive sector for the production of various housings and shafts. The ALX 2500 is available in turning lengths of 11.8", 19.7" and 39.4".

The ALX 2500 with its tailstock and 12 powered tools in the BMT turret can also handle more complex components. Rapid traverses of up to 98 FPM and the high-performance turnMASTER spindle with a speed of 3,500 RPM and a torque of 587 ft-lbs. provide the necessary power and dynamics. Its accuracy is 0.4 µ.

The ALX 2500 increases process reliability with its optimum chip flow and simple chip disposal, which is effected at the front. Maintenance parts can also be reached quickly and simply from there. The user-friendly, ergonomic design of the ALX 2500 is continued for the controls, where DMG MORI utilizes the 12.1" COMPACTline with MAPPS Pro for 11.8" and 19.7" turning lengths, and the 15" SLIMline with MAPPS IV for the longer versions.

Because flexible serial production plays a key role in automobile construction, DMG MORI offers the ALX 2500 with the optional installation of a gantry loader, which enables virtually unmanned production. Modular expansions for the automation solution, such as a measuring unit or deburring unit among others, are also available for even higher process integration.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI

(364-6674)

www.us.dmgmori.com