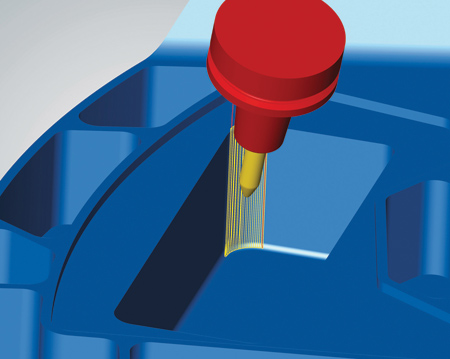

Conical barrel cutter: finish prismatic fillets with a high feedrate.

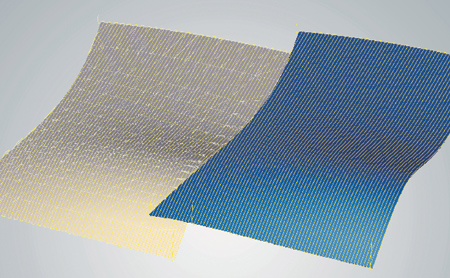

hyperMILL 2019 high precision surface finishing mode (right) compared to conventional mode on left

OPEN MIND Technologies AG, a developer of CAD/CAM software solutions worldwide, has introduced hyperMILL 2019.1, a new version of its advanced, comprehensive CAD/CAM software suite. hyperMILL 2019.1 has a range of new features and enhancements including an expanded finishing module in the hyperMILL MAXX machining performance package, process optimizations such as a new thread milling module, a new function for reducing calculation times, tool database flexibility and CAD optimization. hyperMILL 2019.1 will be demonstrated at EASTEC.

"We are very pleased to launch 2019.1 hyperMILL," said Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. "We have expanded functions that offer even further improvements for cycle time reductions, higher surface finish quality, increased user convenience and more, keeping the hyperMILL suite at the forefront of CAM technology."

5-Axis Prismatic Fillet Finishing

The new 5-axis prismatic fillet finishing function in hyperMILL MAXX machining enables the geometry and automatic inclination of barrel cutters to be applied similar to high feed cutters, using a plunging and pulling movement at high feed rates. Maximum performance is attainable using conical barrel cutters (also known as arc segment or circle segment end mills). Ball or bull nose end mills can also be efficiently utilized with this milling strategy.

Improved Surface Finishes

The profile milling technique in 2019.1 has a new option that improves the quality of machined surfaces. Traditional CAM software processing uses a close-approximation mesh surface for machining calculations. A benefit of the mesh approach is to standardize CAM processing, even in cases when the design model has imperfections. OPEN MIND has implemented new techniques in hyperMILL 2019.1 for machining directly to the model surface, which has improved surface finishes.

Enhanced Process Optimizations

Among the process improvements in 2019.1, the totally updated thread milling module is easy to program and supports a large number of thread milling types while simplifying selection and milling direction options.

Also new to 2019.1 is the elimination of cycle recalculation requirements, improving processing speed. Recalculation cycles are no longer required when job I.D. numbers are changed or when fixture positions change. In addition, improved tool management users now have the option to individually expand the tool database in hyperMILL 2019.1, allowing the ability to store order numbers, pricing and tool life detail.

CAD Optimized for CAM

hyperCAD-S in the 2019.1 suite, which is specially optimized for CAM requirements, now includes polyline management, enabling CAD functions such as lengthening or shortening to be applied by the polylines element type. Polylines can also be machined similar to all other elements, with trim, join, orient or select.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com

EASTEC 2019 Booth 5228