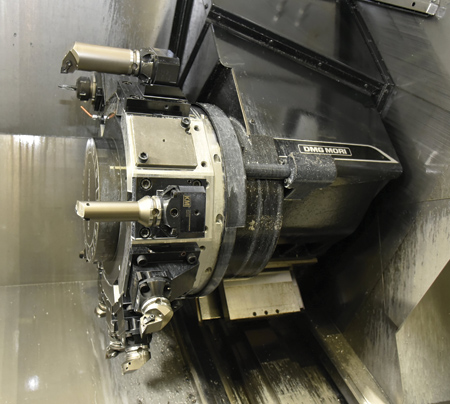

Anthony Machine has been using KM throughout the shop for years. "When the time came to equip their new Y-axis lathes from DMG MORI with quick-change tooling, the choice was clear," said a spokesperson.

After seeing the benefits of using KM on their new NLX machines, Anthony Machine is planning to expand its use of quick-change tooling to other parts of the shop.

The speed and repeatability of KM quick-change tooling has made a "striking difference on many of the jobs at Anthony Machine," said a spokesperson.

Mohsen Saleh and CNC machinist setter Mark Garland discuss a workpiece produced on one of Anthony Machine's DMG MORI NLX 3000 1250 universal turning centers.

"For more than three decades, Kennametal's KM brand of quick-change tooling has been making machine shops more efficient. KM is designed to provide shorter set-up times, greater flexibility, higher levels of machine utilization and the ability to meet the industry's increasingly stringent requirements head on," said a Kennemetal spokesperson.

One KM user is Anthony Machine Inc. Since 1946, the San Antonio job shop has served a variety of industries, including oil and gas, mining, transportation and power generation. With all that precision machining experience, there is little this San Antonio job shop cannot handle. However, after the company purchased a pair of NLX 3000 1250 universal turning centers from CNC machine builder DMG MORI - the shop's first Y-axis, live-tool lathes - Anthony's manufacturing team was challenged with making the most of that new investment.

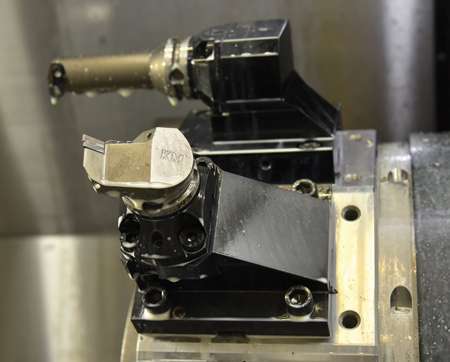

Kennametal Senior Sales Engineer Mark Davis was there to help, just as he has been for the past decade. He explained to Anthony that the best way to reduce set-up times and maximize the new machines' potential would be to equip them with Turret Adapted Clamping Units (TACU) and KM quick-change toolholders.

"The TACU system supports everything from KM32 up to KM63," said Davis. "We offer blocks for both static and driven tools, and can tool up lathes from Okuma, Haas, Mazak, Doosan and of course DMG MORI - pretty much all of the major machine tool builders, with more coming online all the time. This makes it both easy and cost-effective for our customers to equip more than 80 models of CNC turning centers with a fast, flexible and accurate quick-change toolholding system."

According to Anthony Machine Manufacturing Technologist Daniel Goller, the decision to adopt TACU and KM for the new machines was an easy one. "Over the years, we have built a number of KM-equipped custom toolholders for deep boring and other machining operations on our CNC lathes and machining centers, and we use Kennametal on several of the shop's manual turret lathes to overcome limitations with available tool positions," said Goller. "On more than one occasion, we have earned new business because KM was able to achieve tolerances and surface finishes that others could not do with conventional tooling."

Anthony's Operations Manager Mohsen Saleh agreed. "The differences are striking," said Saleh. "Compared to the traditional wedge and screw-style blocks that come standard on most machines, the KM-equipped TACU units are both faster and more accurate. We routinely hold tolerances of 0.0005 inch and I am told that part size does not change from one clamping to the next. The turret is less crowded, everything is easier to get at and you do not have the chatter and deflection that you often find with your typical straight shank tools and set-screw type boring bar holders."

"Anthony's experience with TACU is what we have come to expect from KM," said Davis. "Considering the breadth of the platform, its accuracy, and especially its flexibility, it is quickly become the de facto industry standard in quick-change tooling."

Saleh summarizes Anthony's recent success with a bit of company perspective. "We bought our first CNC machine in 1986," said Saleh. "At that time, we were using a well-known competitive brand and then Kennametal came knocking. What first struck us was their service-oriented attitude. They have always been willing to come in and work with us on applications, which together with the quality of their products is why they have since become our preferred tooling supplier. We are always competing against smaller, lower-cost shops and in order to continue winning new business in this environment, we have to adopt the latest in advanced tooling and machine tool technology. This is what has given us the edge and Kennametal is a big part of it."

For more information contact:

Kennametal Inc.

600 Grant Street

Suite 5100

Pittsburgh, PA 15219

724-529-8033

www.kennametal.com

Anthony Machine Inc.

1235 W Laurel

San Antonio, TX 78201

210-734-5121

www.anthonymachine.com