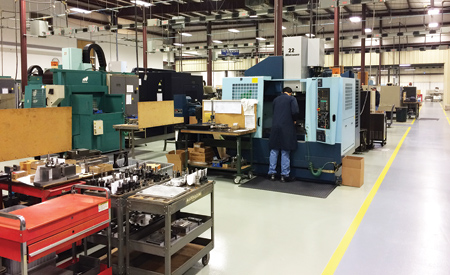

Part of Paramount Machines' immaculate aerospace machine shop floor.

The Keller MB 17-SK skimmer package on one of Paramount's Hwacheon machines.

The Keller MB 17-SK will return any coolant it removes back to the sump. Any oil removed is held in the unit, and drained on a weekly basis. This eliminates costly coolant loss and messy waste container overflows.

Ron McLeish, Facilities Manager at Paramount Machine, needed a way to keep the coolant clean in his 40+ machines. As an AS 9100 certified shop, Paramount is always looking for ways to reduce its environmental footprint, and recycling coolant was a key component to reducing its overall waste stream. A search for a solution led McLeish to Keller Products, provider of metalworking fluid recycling products.

The visit from Paramount's local Keller representative focused on several larger machines that would use the Keller TKO units to keep them clean. However, McLeish had requirements beyond those areas, and was looking for solutions to be dedicated to the rest of the machines in the shop. McLeish found that the Keller MB 17-SK Black Magic skimmer package best fit his needs.

The Black Magic skimmer package incorporates elements that eliminate two classic problems with skimmers: excess coolant removal and messy, overflowing collection buckets. The Keller skimmer package features a cotton felt belt, which is designed to provide enhanced oil removal and durability. The skimmed fluid is delivered to a "Skimallessor" tank, which collects the oil and returns and coolant back to the sump. The entire package is contained in a convenient bracket that is adjustable, and utilizes a magnetic mount for easy installation.

McLeish installed the first skimmer package on a large Matsuura to check the performance. "The results were excellent," he said. "The sump was clean, and the oil drained from the Keller skimmer was solid oil. It eliminated coolant waste." A plan was made to purchase enough units, over a period of time, to satisfy the requirements for the whole shop.

As for the benefits of the program, McLeish stated, "If dirty coolant machined better, no one would ever dump it. Keeping the coolant clean yields better tool life, better part finishes, less downtime and less waste. For the cost of these units, the payback is immediate."

Paramount is a family owned and operated machine shop. "We pride ourselves on delivering quality parts, and recognize the importance of investing in ongoing shop maintenance items to improve performance and keep operating costs down," said McLeish.

For more information contact:

Paramount Machine Company, Inc.

138 Sanrico Drive

Manchester, CT 06042

860-643-5549

para-co@att.net

www.paramountmachineco.com

Jonathan Strauss, Sales Manager

Keller Products, Inc.

6 Ledgerock Way, Unit #6

Acton, MA 01720

800-352-8422 / 978-264-1911

info@kellerfilters.com

www.kellerfilters.com