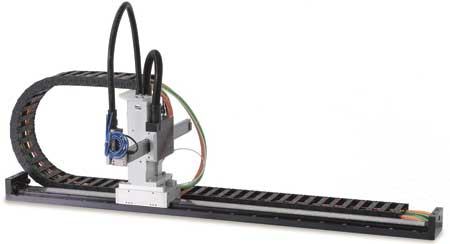

Permanently connected to the basic axis is the HP series direct drive pick and place module, which forms the 2nd and 3rd axis.

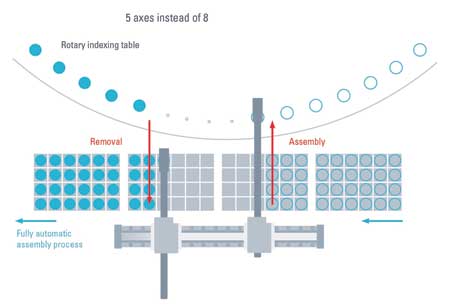

Two pick and place units can be positioned on a basic axis with a length of up to four meters and can work independently of each other.

The major advantage of WEISS' 3-axis system is that end users only pay for what they actually need. The key to this handling technology relies on standard components that have been proven and can be combined to create perfectly matched sub-systems.

Permanently connected to the basic axis is the HP series direct drive pick and place module, which forms the 2nd and 3rd axis. The strokes of the axes can be precisely matched to the dimensions of the tray.

The WEISS automated process is flexible. For example, two pick and place units can be positioned on a basic axis with a length of up to four meters and can work independently of each other. The customer effectively pays for six axes (basic axis with two carriages and two pick and place units) and utilizes the rail of the basic axis twofold.

The handling product from WEISS operates completely without gears, which is made possible by linear drives.

While ideal for palletizing and tray packing applications, the 3-axis system can also be leveraged for a wide range of associated applications, including automotive, medical, inspection and electronics. The system is currently being used for the inspection of circuits in the production of electronic cigarettes.

"Importantly, end users can leverage the WEISS Application Software (WAS) to enable simple and intuitive commissioning of the system's most important parameters," said a company spokesperson. "This makes life easier for smaller and medium-sized plant engineering companies in particular.

"The axis combinations are not only easy to commission, but the demounted individual modules can also be used in other automation processes at a later stage. This may take some time to pay off, but significant dividends are ultimately achieved."

For more information contact:

WEISS North America, Inc.

3860 Ben Hur Avenue

Willoughby, OH 44094

888-934-7762

info@weissna.com

www.weissna.com