The Robo-Rivet can accommodate many types and sizes of blind rivets.

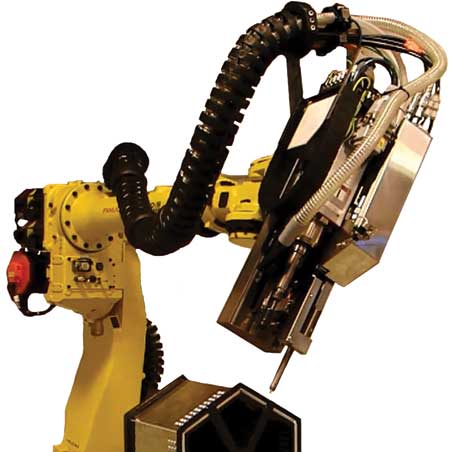

The Robo-Rivet automated drill and rivet tool

The Robo-Rivet provides a solution for automating the blind rivet fastening process.

ARM Automation recently introduced the Robo-Rivet automated drilling and riveting system designed to support the aggressive shift towards lightweight and dissimilar materials within high throughput manufacturing environments.

"The move away from steel has prompted manufacturers to explore fastening technologies outside of welding, such as joining with adhesives and mechanical fasteners," said a company spokesperson. "The technical advantages of the blind rivet make this fastener an ideal choice for single-sided fastening; however, the fastening process has traditionally required manual intervention by an operator. The Robo-Rivet now allows manufacturers to automate the blind rivet fastening process on the production line.

"By automating the drilling and riveting processes, the Robo-Rivet effectively decreases the fastening cycle time when compared to the manual process. Automation also complements the characteristics of the blind rivet by increasing the joint quality through matched drilling and repeatable fastening. Other benefits include labor and ergonomic savings, fastening capabilities in hazardous locations and enhanced productivity."

The Robo-Rivet features servo controlled rivet and drill axes, automated rivet feed and pintail collection, fastener inspection, chip collection, process data acquisition and adjustable drill/rivet recipes for each fastener location. The Robo-Rivet tool can be mounted onto a robot for use with complex structures or attached to a stationary stanchion for linear fastening.

The Robo-Rivet is suitable for use in the automotive, agriculture equipment, rail car, truck and trailer manufacturing environments. Typical applications include aluminum structure fastening, mixed materials joining and fixation for adhesive bonding.

For more information contact:

ARM Automation Inc./Robo-Rivet

14121 West Hwy 290, Bldg 4

Austin, TX 78737

512-894-3534

info@robo-rivet.com

www.robo-rivet.com