(l-r) Jim Krisovitch and Dave Krisovitch, owners of Micro Tool Company, Bethlehem, PA.

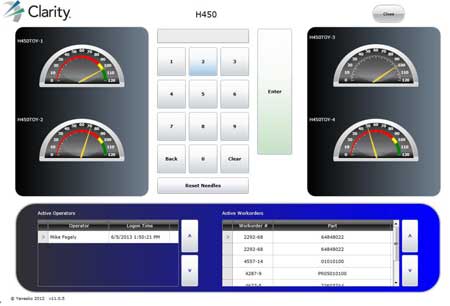

An operator at Micro Tool Company logs onto the Clarity Operator Dashboard.

Clarity's live monitoring software features allow operators to be actively involved in overall plant performance.

The Operator Dashboard provides the operator with live performance feedback of the machine cell.

Clarity Monitoring software's Manager Dashboard allows management to see real-time productivity of the entire shop.

Micro Tool Company in Bethlehem, PA, has spent millions of dollars on multi-axis robotic machining systems. "After many years of investing in the latest automated equipment to raise productivity levels, our goals were to give better visibility on all of our operating equipment from a productivity and troubleshooting standpoint and to enable our personnel to play an active part," said David Krisovitch, President. "Live-monitoring software tied directly into the machine tools seemed like a viable option to achieve this goal."

After careful evaluation, Micro Tool chose Clarity live monitoring software. "Clarity's approach to live monitoring is a measurement tool for management and operators," said Krisovitch. "The Operator Dashboard provides the operator with live performance feedback of the machine cell. This allows operators to self-manage and understand their performance against what is being expected out of the work cell center. Now the operators can use Call Buttons for help if they cannot reach the desired rate of parts coming off the work cell center and get help. The empowerment of the operators to influence and raise the overall performance of the plant is a unique Clarity feature."

Micro Tool currently has 13 of its machine tools employing Clarity's software. "Our goal is to get 20-30 machines online," said Krisovitch. "We have found an average increase in productivity of 15%, with positive feedback from employees using the system. Employees receive real-time feedback of their production rates versus shop production standards. Management sees real-time productivity of the entire shop and is able to give immediate attention to problem areas."

Krisovitch stated that the Reason Codes for downtime and Operator Call Buttons are also helpful features within Clarity's Operator Dashboards. "We now have the ability to track and assign reasons for downtime and give the operators a simple way to call for help, inspection or forklifts without leaving their work cell center," he said. "These Call Buttons really help in keeping operators at their equipment producing product instead of hunting around the building while the machine sits idle."

At its facility that houses 45,000 sq. ft. of manufacturing space, Micro Tool performs CNC turning and milling of precision component machine parts for the medical, aerospace, light industrial, communications and other industries. With various brands of machines - including Haas, Matsuura, Mazak, Mori Seiki, Star CNC and Sunnen, to name a few - Micro Tool can CNC turn/mill up to 13-axis and CNC mill up to simultaneous 5-axis. The company can perform Swiss turning from 16-32 mm capacity and features extensive robotic automation with vision systems and machine tool integration.

Micro Tool is ISO 9001:2008 registered and has the following manufacturing capabilities:

- Micro hole drilling to .0004" diameters

- Cyrogenic Dewar manufacturing expertise

- CNC robotic welding (TIG/MIG)

- Vaporless cleaning to medical oxygen requirements

- ERP system Infor Visual Enterprise (Clarity directly integrated with the database).

Founded in 1965 by Bill Krisovitch, Micro Tool currently has 48 employees and is co-owned by Bill's sons David and Jim. "For 50 years we have provided our customers with precision machining in a timely and cost-effective manner with the highest level of quality," said David Krisovitch. "Whether it be a small medical device, turbo-machinery blading or an 8 ft. long 1,000-lb. precision shaft, we have the expertise needed. If you can imagine it, Micro Tool Company can create it."

For more information contact:

David Krisovitch

President

Micro Tool Company

284 Brodhead Rd.

Bethlehem, PA 18017

610-882-3740

dave@microtool.com

www.microtool.com

Clarity Monitoring

800-770-4229

info@claritymonitoring.com

www.claritymonitoring.com