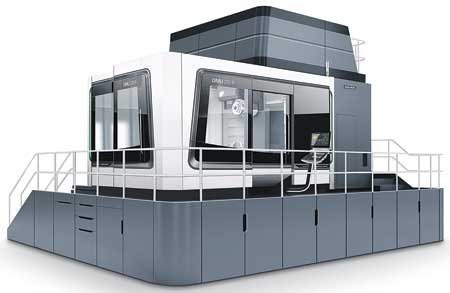

The DMU 270 P machines large parts up to 12,000 kg.

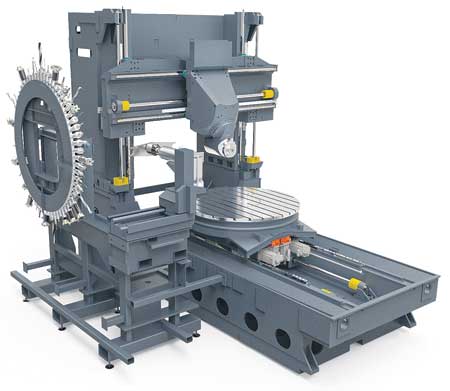

The rigid structure of the gantry machine concept with vertically traversing crossbeam and hydraulic weight compensation has been enhanced.

DMG MORI offers gantry machines for the large part manufacturing industry. Compared with the DMU 210 P, the latest DMU 270 P gantry machining center has longer XYZ travels of 2,700 x 2,700 x 1,600 mm. They represent increases of 50% in the transverse direction and by approximately 30% in the longitudinal and vertical directions. The work area is increased by 235%. The interference contours are also improved due to the newly designed milling head. A further advantage is that the space requirement has been kept low by appropriate design of the additional components. Maximum workpiece dimensions are increased to a 2,800 mm diameter and 1,800 mm height with a permissible workpiece weight of 12,000 kg.

The rigid structure of the machine concept with vertically traversing crossbeam and hydraulic weight compensation has been further enhanced. The basic machine is made entirely of high-quality castings (GGG60). The B-axis milling head with a swivel range has been extended from 210° to 250° and is capable of swiveling to 30° in the negative direction. Together with the larger B-axis bearing, DMG MORI reported this results in a milling head housing with 20% higher rigidity, extending the range of applications. Typical applications include tool making, moldmaking, mechanical engineering, aerospace industry, energy management and medical engineering. Idle times are reduced due to the increased swivel speed of the B-axis with 30 RPM and a full swivel time of 1.5 seconds. The integral cables are designed for longer service life.

The newly developed B-axis works in conjunction with a more rigid NC rotary table that can be more accurately positioned. With a larger bearing and improved toolholding, this provides a torque of 34,000 Nm and is driven at an increased maximum speed of up to 14 RPM by means of two compact gearboxes that are electrically braked. In addition to the higher B-axis swivel speed and the enhanced NC table, the DMU 270 P offers high dynamics.

The powerMASTER 1000 motorized spindle with 9,000 RPM, a maximum of 77 kW and 1,000 Nm torque is designed for effective heavy-duty chip removal. As well as the standard SK 50 / HSK-A 100 motor spindle with 12,000 RPM, 44 kW and 288 Nm torque, five further spindles are available as an option - including a unit rated at 15,000 RPM with 52 kW at 430 Nm or the 35 kW spindle with HSK 63 interface and a maximum of 18,000 RPM for high-speed cutting. According to the company, the larger-than-average range of main drives is supplemented by the offer of the HSK 100 gear-driven spindles with 1,550 Nm at 6,300 RPM and 44 kW.

As an alternative to the B-axis arrangement, the range of gantry machine modules includes an A-axis milling head housing with swivel axis parallel to the X-axis, which accommodates the appropriate motor spindles.

In conjunction with the high machine rigidity, DMG MORI reported that a constant overall machine temperature control with the cooling of all internal heat sources on the DMU 270 P leads to a further improved positioning accuracy compared with the smaller DMU 210 P gantry machine with Pmax < 9 / 10 / 9 um. For this purpose, cooling measures have been implemented on all ballscrews, housings and motors of the main and feed drives, all linear axes and the B-axis and C-axis of the milling head and rotary table. A further effective measure is the temperature control of the frame and machine bed. In addition, insulation at the rear of the electrical cabinet shields any heat produced, which, together with improved electrical cabinet cooling, helps prevent any negative effects. The electronic compensation devices, which are specially matched to the DMU 270 P, eliminate any residual displacement that may be caused by heat or the effects of static or dynamic forces.

The Spindle Growth Sensor (SGS), included as standard with the thermo-symmetrically designed gantry machine, prevents axial spindle displacement. A temperature control feature for the whole coolant system and a Thermoshield for shielding the machine bed from airflow are also available.

"The DMG MORI modules for the DMU 270 P gantry machine enable production time to be increased and idle times to be further reduced and provide an additional range of automation equipment," said a company spokesperson. "The consequential growth in universality and productivity for 5-axis milling and the future combination with turning operations in a single set-up form the basis for a significantly extended range of applications." The wheel magazine, similar to the 4th generation duoBLOCK machines, enables rapid tool changeover. An upgrade for the standard wheel with 63 pockets to 123, 183 or 243 pockets in the version with four wheels enables the machine to be ideally matched to customer requirements. The wheel magazine is also compact for minimal space requirement. The productivity of the gantry machine is also improved by the increase in NC table speed in rapid traverse mode and the increased swiveling speed of the milling head.

Planned options include the future DMC 270 U version of the machine with pallet changer, and the DMC 270 FD fitted with a milling/turning table to form a gantry milling/turning center. Additional automation devices, such as the use of a pallet magazine or the integration of several DMC 270 U gantry milling centers with a linear pallet magazine to form flexible manufacturing systems, are already planned.

Energy savings have been implemented into the DMU 270 P. The enhanced and optimized machine temperature control necessitates the use of efficient, energy-saving cooling units. In addition, the cooling power required at any particular time is automatically adjusted to the cooling requirement of the machines. Likewise, the pumps, such as the coolant pumps, are classed as energy efficient due to speed controllers. An automatic power display, for example on the CELOS interface, not only shows the machine operator the current energy consumption but also prompts the appropriate savings.

The large work area of the DMU 270 P gantry machine with a volume of 11.7 m3 can be easily accessed from the front, the side or from above. The improved view of the work area makes for user-friendly machine ergonomics for effective set-up and in automatic mode. The work area is also fully clad in stainless steel and, if it should be necessary to change a window, this can be carried out from the outside. The DMU 270 P is offered with CELOS with 21.5" ERGOline and Siemens. CELOS APPs provide the user with integrated management, documentation and visualisation of order, process and machine data. CELOS is compatible with PPS and ERP systems, can be networked with CAD / CAM applications and is ready for future-oriented CELOS APP extensions. As standard, the machine is equipped with Operate 4.5 on Siemens 840D solutionline including 19" ERGOline.

For more information contact:

DMG MORI USA

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

www.dmgmori.com

Southwest

DMG MORI - Dallas

9001 Currency Street #200

Irving, TX 75063

972-929-8321

www.dmgmori.com

TX, LA

DMG MORI Ellison Technologies - Dallas

9001 Currency Street #200

Irving, TX 75063

972-812-5500

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Houston

3403 N. Sam Houston Pkwy. West #100

Houston, TX 77086

713-365-9500

www.ellisontechnologies.com

OK

DMG MORI - Tulsa

7633 E 63rd Place, Suite 300

Tulsa, OK 74133

918-932-2893

www.dmgmori.com

Southeast

DMG MORI - Charlotte

4345 Morris Park Drive

Charlotte, NC 28227

704-940-3380

www.dmgmori.com

VA, NC, SC

DMG MORI Ellison Technologies - Charlotte

4345 Morris Park Drive

Charlotte, NC 28227

704-545-7362

www.ellisontechnologies.com

S. AL, GA, MS, TN

DMG MORI Ellison Technologies - Nashville

7118 Crossroads Blvd.

Brentwood, TN 37027

615-661-6800

www.ellisontechnologies.com

FL

DMG MORI - Clearwater

4585 140th Ave. North, Suite H1008

Clearwater, FL 33762

727-530-1490

www.dmgmori.com

Northeast

DMG MORI - Newark

1160 Parsippany Blvd, Suite 103

Parsippany, NJ 07054

973-257-9620

www.dmgmori.com

DMG MORI Tyler Machine Tool

111 Ledge Rd.

Seabrook, NH 03874

603-474-7730

www.dmgmori.com

DMG MORI Tyler Machine Tool

68 Nutmeg Road South

South Windsor, CT 06074

860-528-4010

www.dmgmori.com

Boldt Machinery, Inc.

4803 Pittsburgh Ave.

Erie, PA 16509

814-833-9836

www.boldtmachinery.com

Boldt Machinery, Inc.

104 Boss Rd.

Mattydale, NY 13211

315-463-5754

www.boldtmachinery.com

MD, DE

DMG MORI - Charlotte

4345 Morris Park Drive

Charlotte, NC 28227

704-940-3380

www.dmgmori.com

DMG MORI Ellison Technologies - Charlotte

4345 Morris Park Drive

Charlotte, NC 28227

704-545-7362

www.ellisontechnologies.com

Midwest

DMG MORI - Chicago

2400 Huntington Boulevard

Hoffman Estates, IL 60192

847-593-5400

www.dmgmori.com

DMG MORI Ellison Technologies - Chicago

4630 Weaver Parkway

Warrenville, IL 60555

630-393-8900

www.ellisontechnologies.com

DMG MORI - Cincinnati

5333 Mulhauser Road

Hamilton, OH 45011

513-874-2736

www.dmgmori.com

DMG MORI Ellison Technologies - Cincinnati

5333 Mulhauser Road

Hamilton, OH 45011

513-874-2736

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Cleveland

6955 Treeline Drive

Brecksville, OH 44141

440-546-1920

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Davenport

145 West 76th Street

Davenport, IA 52806

563-388-0800

www.ellisontechnologies.com

DMG MORI Ellison Technologies - St. Louis

16 MB Corporate Park Ct.

St. Charles, MO 63301

636-946-7077

www.ellisontechnologies.com

DMG MORI - Detroit

29050 Cabot Drive

Novi, MI 48377

248-324-1928

www.dmgmori.com

DMG MORI Ellison Technologies - Detroit

29050 Cabot Drive

Novi, MI 48377

248-324-1928

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Grand Rapids

1550 Gezon Parkway SW, Suite B

Wyoming, MI 49509

616-261-8665

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Indianapolis

8930 Bash Road, Suite A

Indianapolis, IN 46256

317-577-3723

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Milwaukee

N27 W23750 Paul Road

Pewaukee, WI 53072

262-523-3400

www.ellisontechnologies.com

DMG MORI Ellison Technologies - Minneapolis

13400 10th Avenue North

Plymouth, MN 55441

763-545-9699

www.ellisontechnologies.com

DMG MORI - Kansas City

7500 College Blvd, 5th Floor

Suites 520/521/522/524

Overland Park, KS 66210

913-871-1373

www.dmgmori.com

DMG MORI - Wichita

3450 N Rock Rd

Building 500, Suite 505

Wichita, KS 67266

316-425-7993

www.dmgmori.com

West

DMG MORI - Los Angeles

5740 Warland Drive

Cypress, CA 90630

562-430-3800

www.dmgmori.com

Southern CA

DMG MORI Ellison Technologies - Los Angeles

9890 Pioneer Blvd.

Santa Fe Springs, CA 90670

562-949-8311

www.ellisontechnologies.com

Northern CA

DMG MORI Ellison Technologies - San Francisco

2607 7th St. Suite C

Berkeley, CA 94710

866-814-7238

www.ellisontechnologies.com

WA, ID, MT

DMG MORI Ellison Technologies - Seattle

19625 62nd Ave. South, Suite A109

Kent, WA 98032

253-872-1661

www.ellisontechnologies.com

OR

DMG MORI Ellison Technologies - Portland

10159 SW Commerce Circle #K

Wilsonville, OR 97070

503-682-3280

www.ellisontechnologies.com

AZ

Ellison Machinery

1610 S. Priest Dr. #101

Tempe, AZ 85281

480-968-5335

www.ellisonaz.com

CO

Triad Machine Tool Co., Inc.

7885 West 48th Avenue

Wheat Ridge, CO 80033

303-424-0268

www.triadmt.com

UT, ID, MT, WY

New West Machine Tool Technologies

7990 South 1530 West

West Jordan, UT 84088

801-561-2001

www.newwestmachine.com