Cobot welding with FASTSUITE

Robot team synchronization with FASTSUITE

During a supply chain crunch, an integrator's ability to swap out one robot brand for another cut the lead time from 36 weeks to eight weeks. FASTSUITE, brand-agnostic simulation software from CENIT, helped keep the project on track.

"As labor shortages and calls for higher productivity fuel demand for more automation, robot suppliers are striving to meet demand for their products," said a company spokesperson. Robot sales in North America set a new record in 2021, with 39,708 units sold, a 28% increase over the previous year, according to the Association for Advancing Automation. Although this post-crisis boom is expected to subside in 2022, robots will continue to be in high demand."

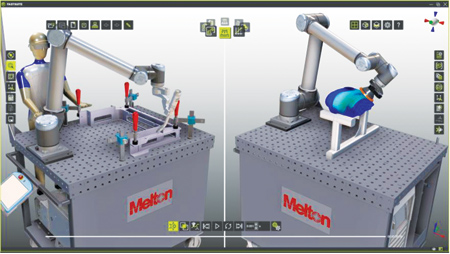

FASTSUITE simulation and offline programming software creates 3D simulations of entire automaton cells before they are built. The brand-agnostic platform allows integrators to substitute different robot arms when a robot supplier's lead time could delay a project.

"Swapping out a yellow robot for a red one might seem simple, but integrators must consider different robot reach and axis limits when designing the layout for an automation cell. Software that simulates robot operation and interaction with other equipment helps engineers determine the optimal cell design," said the spokesperson.

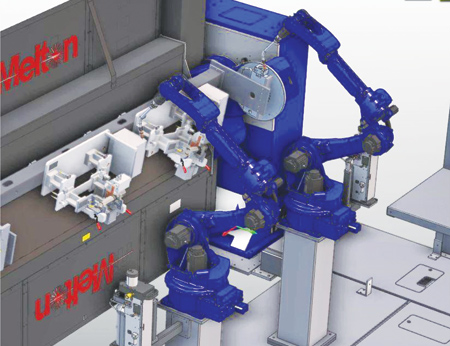

System integrator Melton Machine & Control Company designs and builds robotic arc welding cells and other automation systems for the automotive, agriculture and construction industries. Recently, the integrator had an issue with a material handling project that was already designed around a particular brand of robot. That robot's manufacturer said they would be unable to deliver the robot in the expected timeframe. The new lead time would be 36 weeks.

Unable to wait that long, Melton Machine had to substitute a different robot brand with a shorter lead time. Normally that type of change, if simulated in the original robot manufacturer's software, would require a lot of time and effort to reprogram in the new robot's brand-specific software. But FASTSUITE software is brand agnostic, making for an easier swap.

"If we do the simulation in FASTSUITE and then the customer wants to specify a different robot or we need to swap it out due to a supply chain issue, we will still need to reprogram, but all the fundamentals are already there," said Glenn Archer, VP of Sales & Marketing for Melton Machine. "The advantage is that any robot you grab, all the limits are already set up, so robot reach studies and other parameters are already handled. It is quicker and less expensive to change out the robot if we have done it through the FASTSUITE path."

FASTSUITE software provides an extensive library of nearly 800+ robot arms from all major manufacturers. Reachability studies, axis limits, etc. are all handled by CENIT software, no matter the robot brand and no matter the process, whether it is material handling, welding, material removal or assembly. Using CENIT's brand-agnostic software, Melton Machine was able to swap out a different robot and drop it into the existing simulation.

"We were able to get the new robot in eight weeks and turn it around quickly," said Archer. "The customer was back on track."

For more information contact:

CENIT North America, Inc.

691 N Squirrel Road, Ste. 275

Auburn Hills, MI 48326

248-309-3240

info@cenit.com

www.cenit.com

Melton Machine & Control Company

901 Melton Drive

Washington, MO 63090

636-239-7765

www.meltonmachine.com