The Dynamic 9D LADAR captures dimensional and surface geometries.

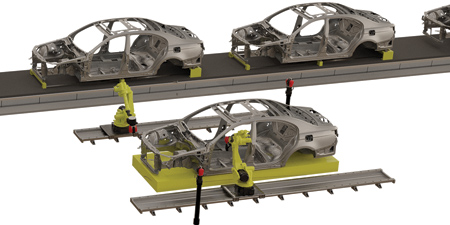

Automated near-line inspections with 9D LADAR.

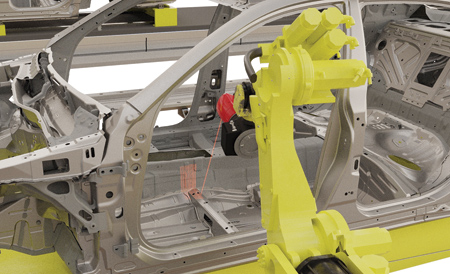

9D LADAR performing in-line car body inspection.

API offers its Dynamic 9D LADAR, an innovative laser detection and ranging system that captures dimensional and surface geometry data.

"Dynamic 9D LADAR offers the world's first interferometry-based LADAR system incorporating Optical Frequency Chirping Interferometry (OFCI) technology," said a company spokesperson. "9D LADAR's accurate data collection of production measurements represents the next generation dimensional inspection solution, replacing traditional, off-line, large volume coordinate measuring machines (CMMs) and near-line and in-line inspection solutions using optical laser-line and structured light scanning sensors."

The 2-axis 9D LADAR system processes measured data at the rate of 20,000 points per second and with scanning speeds of 0.2 seconds/sq. cm. Furthermore, 9D LADAR's high Dynamic range is insensitive to target reflectivity, can measure translucent materials and is able to measure target features with up to an 85° incidence angle. High-density raster scanning delivers up to 50 lines/second with 0.1 mm line spacing. 9D LADAR's on-board scale reference system provides 2D and 3D accuracies of 6 µm/m, providing comparable accuracies to benchmark accuracy large volume CMMs.

Dynamic 9D LADAR's compact design, weighing just 10.4 kg, incorporates an integral controller with ethernet communication, allowing for seamless integration to both portal CMM frames or 6-axis industrial robots, including 7-axis rail mounted configurations.

9D LADAR's iVision smart camera system provides instant part visualization for automated scan path planning, offering both automated feature and targeted region measurement, along with remote measurement operation viability.

API's Dynamic 9D LADAR delivers X, Y, Z, I, J, K data for each generated cloud point along with the addition of RGB data, allowing for scanned data to be imaged directly onto the captured camera image. This capability allows display of characteristics with distinct background color contrast, surface vectors, surface roughness etc., which are difficult to isolate with only the standard 3D point cloud data.

For more information contact:

API

15000 Johns Hopkins Drive

Rockville, MD 20850

757-210-9421

www.apimetrology.com