3D Printing Quality Tracking Module

March 1, 2023

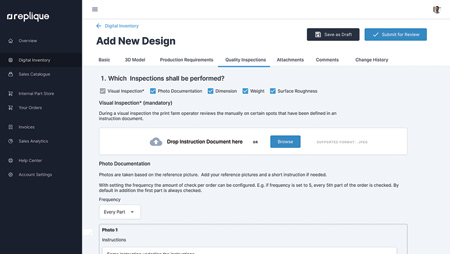

Within the digital inventory, OEMs can choose quality inspections that should be performed on the produced part.

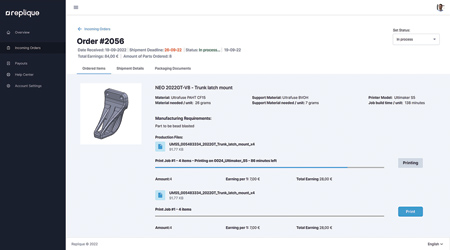

Print farm view of the Replique platform: Encryption of print orders helps ensure that the print farm can only produce parts with requested quality requirements and in the requested amount. All production information is tracked on the Replique platform.

Replique offers RSure, a quality tracking module that enables OEMs to track each of their 3D printed parts directly and ensure that final parts meet necessary quality requirements. RSure allows OEMs to set quality specifications, undertake a digital inspection and trace parts being produced via Replique before the part is sent to customers.

RSure also enables OEMs to include further quality checks for service bureaus to undertake on 3D printed parts, including various certified measurements, functional tests and image upload to the OEM's digital library on Replique. Via the secure platform, OEMs can access and view this information remotely at any time. Replique's encrypted ordering process helps ensure parts are printed in the required amount and in the required quality. The company's digital inventory enables part designs to be stored, managed and ordered internally.

Max Siebert, co-founder and CEO of Replique, said, "As part of BASF, we know that industrial companies need standardized and repeatable production processes, especially when it comes to decentralized manufacturing. With our end-to-end solution, we can ensure traceability while providing repeatable quality and secure encryption of 3D printed parts."

For more information contact:

Replique

info@replique.io

www.replique.io

< back