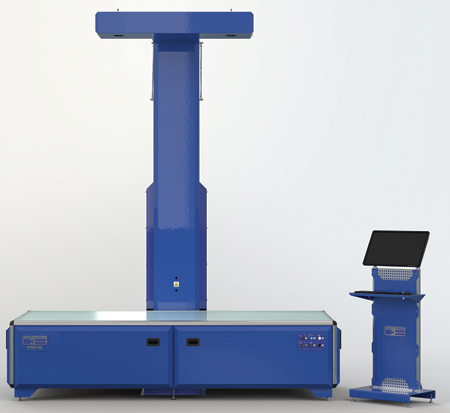

Planar 2D front view

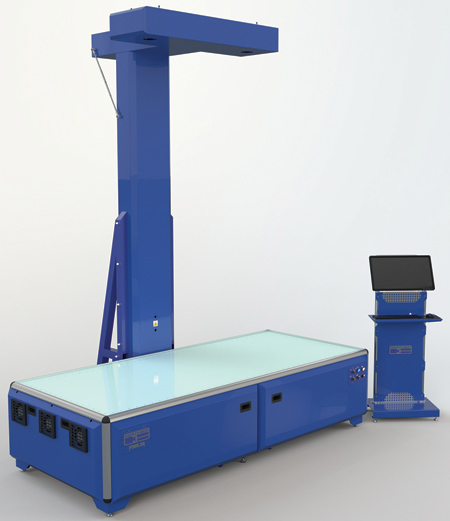

Planar 2 left side view

Exact Metrology represents Planar from InspecVison. This 2D inspection machine allows manufacturers to quickly verify product quality by performing 2D inspection, CAD comparisons and reverse engineering.

According to the company, Planar is designed for shop floor use, requires minimal operator input and increases production throughput across a wide range of applications. These include flat and folded/formed sheet metal components, gaskets and seals, laminations, O-rings, paper acetate and electronic drawings and other opaque and semi-transparent flat materials.

A standard feature on every Planar system is 2D reverse engineering. Existing parts can be reverse engineered quickly, creating dxf or dwg CAD files. The software allows the user to edit and clean the data such as standardization of hole sizes and clean edges and eliminates the need for hand measurement and CAD programming. Physical parts or even paper, acetate or electronic image files can be reverse engineered to create CAD files. Reverse engineering processes can also be carried out in 3D using optional 3D modules. For full 3D capability, users can add Opti-Scan 3D, while the SurfScan module extends Planar to 2.5D.

Opti-Scan 3D is a non-contact white light scanning system that uses a high-speed, high resolution camera and an LED DLP projector to scan the surfaces of an object. Patterns of light are beamed from the projector onto the part, then recorded by the camera and used to create a 3D point cloud of the scanned surface. The Opti-Scan 3D outputs the high resolution points into a number of different file types that can be used in any 3D inspection or reverse engineering software package.

SurfScan integrates seamlessly with the Planar 2D automatic inspection software to allow accurate inspection of both the part's 2D shape and its 2.5D features with a single click. The SurfScan is a high resolution projector that mounts onto the existing Planar vertical column. The projector shines structured light on the part, which is then imaged by the Planar's camera to create a 3D scan of the upper surface of the part. The point clouds created by the system can then be loaded into free and readily available 3D inspection software for comparison against a 3D solid CAD model. Point clouds are also compatible with Geomagic Control, Control X, Polyworks, etc.

"InspecVision Planar offers fully automated one click inspection with machine sizes ranging from 500 m to 3,000 mm. The machine is scratch resistant, features no moving parts, has simple calibration and minimal maintenance, requires minimal training and offers rapid return on investment," said the spokesperson.

For more information contact:

Steve Young

Exact Metrology, Inc.

11575 Goldcoast Dr.

Cincinnati, OH 45249

866-722-2600 / 513-831-6620

stevey@exactmetrology.com

info@exactmetrology.com

www.exactmetrology.com

Dean Solberg

Exact Metrology, Inc.

20515 Industry Avenue

Brookfield, WI 53045

262-533-0800 / 866-722-2600

deans@exactmetrolgy.com

www.exactmetrology.com