The new SINUMERIK ONE is the first-ever digital-native CNC for the machine tool industry.

Machine tool builders benefit from the Digital Twin by speeding up development and commissioning times.

Create MyVirtual Machine masters the challenges of digital transformation.

By combining the real world with the digital world, Siemens will demonstrate how the full potential of data enables machine builders and end users to be flexible and sustainable in their manufacturing.

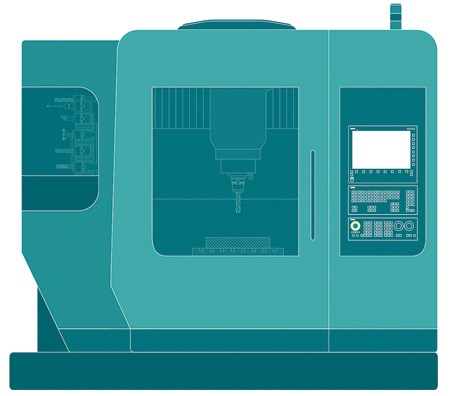

On display in the Siemens booth will be the SINUMERIK family of controls that includes SINUMERIK 828D, SINUMERIK 840D and the new SINUMERIK ONE, the first-ever digital-native CNC.

SINUMERIK 828D is a compact and advanced CNC designed to enable machine tool manufacturers to leverage the full productivity potential of the digital factory in a mid-range control. "With its panel-based design, the 828D can control up to 10 axes and spindles plus two auxiliary axes, making it the perfect CNC system for job shop production," said a company spokesperson.

SINUMERIK 840D sl is suite for modular machine tools used in serial production, 5-axis and multitasking machines. The drive-based 840D can control up to 31 axes and spindles, any number of PLC axes and up to 10 machining channels. It works equally well in a job shop, mid-sized or large production facility.

"The SINUMERIK ONE is the first CNC system to master the challenges of digital transformation in the machine tool industry," said the spokesperson. Real-world machining processes and machine tool behavior can now be simulated in the digital world due to the Digital Twin.

"Using Create MyVirtual Machine, machine tool builders can speed up their development and commissioning times to new levels of quality and efficiency," said the spokesperson. Machine users can also benefit from a "digital first" strategy for their central processes during production when they use Run MyVirtual Machine. Programming, production planning and process optimization can be simulated instead of performing them directly at the machine, and non-productive times are eliminated.

In addition to the SINUMERIK family of controls, Siemens will present its machine tool digitalization portfolio of software apps that are designed to increase manufacturing productivity and accelerate the business of both machine tool builders and machine users. These include Manage MyMachines, Analyze MyMachine, Analyze MyPerformance, Analyze MyWorkpiece, Adaptive Control and Monitoring and more.

Siemens technical experts will be in the booth for demonstrations and to answer all questions.

For more information contact:

John Meyer

Siemens Industry, Inc.

Motion Control Business

390 Kent Avenue

Elk Grove Village, IL 60007

847-640-1595

cnc.marketing.us@siemens.com

www.usa.siemens.com/cnc

EASTEC 2021 Booth 2012