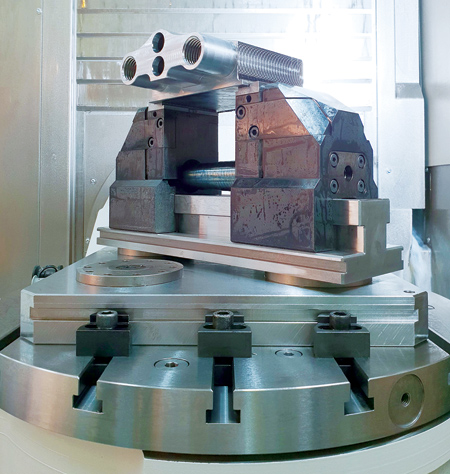

The zero-point clamping system for quick changeover with a 5-axis clamp.

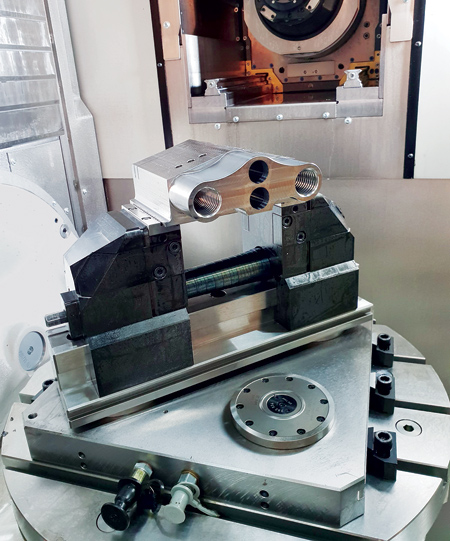

Zero-point clamping system console with K5000 modular clamping device during changeover.

By acquiring Vischer & Bolli Automation, Hainbuch, a German manufacturer of high-precision workpiece clamping equipment, has not only expanded its expertise in the field of automation, but now offers an even wider range of stationary workpiece clamping devices.

While Hainbuch's previous product portfolio for turning, milling, EDM and grinding already covered a wide range of workpieces, since the acquisition it is able to offer custom solutions for workpieces of up to 100 tons or 10 to 20 meters in length. With Vischer & Bolli Automation, the range of stationary devices has been considerably extended. Many stationary clamping devices are available from stock. The modular design of the zero-point clamping system offers a wide range of solutions using standard components, while specific solutions can also be created in accordance with customer requirements.

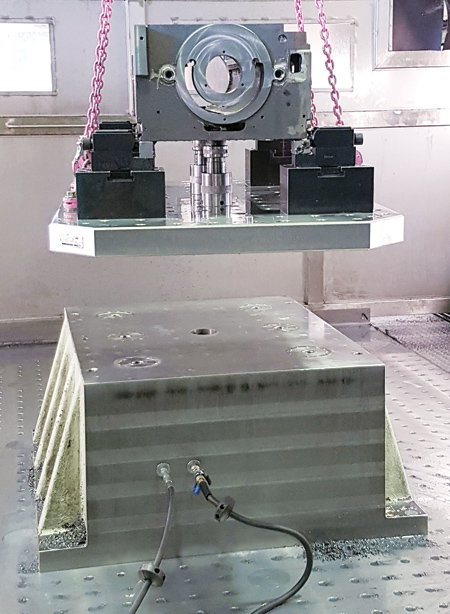

The zero-point clamping system, which is screwed onto the machine table, serves as a base for fast changeovers. This is available in pneumatic and hydraulic versions and is used for manual and automated solutions. To clamp the workpiece on the base, a vise (mechanical, pneumatic or hydraulic), clamping tower, modular clamping device, modular clamping system, magnetic clamping plate or a special device can be used depending on the customer's requirements. This means that an optimal and economic overall solution can be offered for every workpiece, regardless of shape or size. The zero-point clamping system has an accurate clamp and thus helps ensure maximum back force. At the same time, it is low-wear and low-maintenance since it has only three moving parts. Handling and push-off functions are integrated into the system. The modular design provides increased flexibility and time and cost savings in production. With the universal interface, the set-up is done off the machine so no production time is lost.

The patented collet style lock allows easy insertion and removal of the workpiece pallets. With an insertion force of up to 30 kN, the solution offers a vibration-free, positive and non-positive connection between the zero-point clamping system and the workpiece. "Tailor-made custom solutions help to make optimum use of machining potential. Direct installation on machine tables, pallets or fixtures is achieved cost-effectively with installation cassettes," said the spokesperson. The zero-point clamping system can be expanded with optional air blow, support and locking control or external feeds.

According to the company, advantages of the zero-point clamping system include:

- Set-up in parallel with production reduces machine downtime by up to 90%

- Work can be interrupted at any time, providing maximum flexibility for urgent jobs

- Zero-point repeatability < 5 µm

- Cost-effective clamping bolts allow simple retrofitting of existing clamping devices

- Better surface quality due to dynamic, vibration-inhibiting as well as positive and non-positive clamping

- Suitable for automation

- Designed for more than 1 million clamping cycles.

For more information contact:

HAINBUCH America

W129 N10980 Washington Dr.

Germantown, WI 53022

800-281-5734 / 414-358-9550

sales@hainbuchamerica.com

www.hainbuchamerica.com