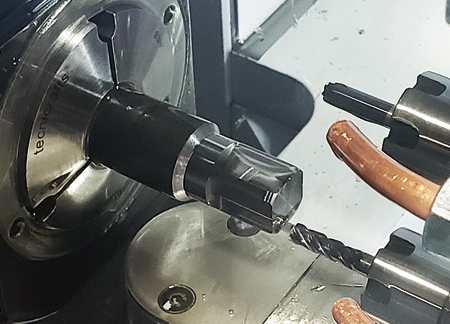

Component for an oil field mud pump is Swiss machined on a Star SR-38 Type B, programmed with Mastercam 2021 Lathe.

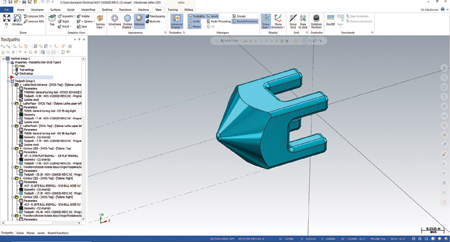

Stainless steel alloy component for an oil-field mud pump was machined using Swiss solution in Mastercam 2021 Lathe.

Mud pump component part is programmed with Swiss solution in Mastercam 2021 Lathe.

In 1987, Edwin DeCora established Ed's Precision Manufacturing, LLC, in Houston, TX, to service the oil and gas, medical, aerospace and agricultural industries. Inspired by his family's fastener business, which was in operation for more than 50 years, DeCora opened his own shop and set out to honor his roots while exploring automated manufacturing methods.

"My family had the shop until my uncle passed away four years ago," said DeCora, Ed's Precision Manufacturing President. "I wanted to expand the business and start my own. The family business was in the modification of fasteners, for which there was a huge need. I took it to the next step and went into the Swiss machine and automation side, which really helped our company grow."

A willingness to take on jobs of any size has led to a steady stream of contracts and a diverse customer base. With capabilities to produce 1/16" dia. custom fasteners and parts up to 36" in diameter and 10' in length, the company's "if you can draw it, we can make it" mantra is paying off. The contract job shop's 40,000 sq. ft. facility nearly doubled in size after completion of a new, additional 35,000 sq. ft. building. Though the bulk of the business comes from the oil and gas industry, Ed's Precision Manufacturing produces large quantities of specialty fasteners.

"We manufacture some oddball stuff," said DeCora. "Mastercam CAD/CAM software really helps us out with that. We can draw anything we need to in the CAD program. We do a lot of fastener specialty items; we try to do the things that nobody else wants to do."

All the company's parts are modeled in the CAD/CAM software, in fact. Ed's Precision does not use any customer-provided modeling due to tolerancing issues. Once the parts are modeled, programmers apply toolpaths, so the entire process is controlled within one software system. For the past five years, the company has focused on and invested in traditional lathe and mill applications. The features in Mastercam Mill-Turn continue to prove its efficiency.

One hurdle that Ed's Precision Manufacturing faces is that it has more work than time to machine. It is a good problem to have, yet one that requires a time-saving solution. When evaluating in-house jobs that could be streamlined, one stood out. The part, an oil-field mud pump component, required extensive machining time. Ed's Precision has been machining this part four times per year over the past four years. The recurring job required a lathe operation followed by a mill operation. Made from a stainless steel alloy, the 0.700" long, 0.450" square intricate part features thin walls. Average machine time was 20 minutes per piece, or 333 hours for a 1,000-part run.

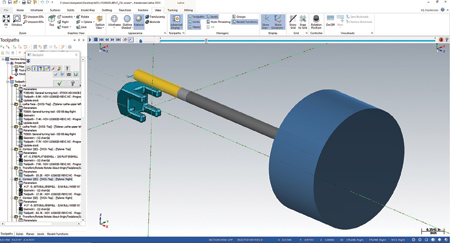

Rather than use two different machines to manufacture the mud pump component, Ben Molinar, Senior CNC Programmer, considered using a Swiss machining application to replace the mill operation. The company owns a Star SR-38 Type B sliding head lathe that offers both guide bush modes (Swiss type) and non-guide bush modes. Known for their versatility and cost effectiveness, CNC Swiss turning machines are ideal for producing small, complex parts or long, thin parts at high production rates. Machine rigidity permits tight tolerances.

"When we bought the Swiss machine and discussed our CAD/CAM software options, we wanted the best value," said Molinar. "We already had Mastercam 2020 and the Beta Program for Mastercam 2021, so it made sense to add the Swiss component. That was a big plus for me as a programmer."

Ed's Precision Manufacturing uses Mastercam Mill 3D, Mastercam Lathe, Mastercam Multiaxis and Mastercam Mill-Turn throughout its shop. In addition, the company relies on the Beta Program for Mastercam 2021, which supports select Swiss machining, including the Star SR-38. By combining seats of Mastercam Mill, Mastercam Lathe and a machine-specific post, the Swiss machining solution utilizes a custom post and creates accurate G-code for a variety of supported Swiss machines.

When weighing their CAD/CAM options, DeCora, company Chief Operations Officer Patrick McLaughlin and Molinar consulted with Chris Leclerc, Swiss Product Specialist at CNC Software, Inc., and Danny Ornelas, Applications Specialist with Mastercam Reseller MLC CAD Systems (Austin, TX).

"Mastercam is so diversified," said McLaughlin. "We have several different brands and controls and the software adapts well to that. If we get a specialty item to machine on an 11-axis Swiss, Mastercam is capable of writing us posts that work. If we then use a 10-axis, Mastercam writes a post that works just as well. We do not have to relearn how to make a part when we switch to a new machine technology."

"The Ed's Precision Manufacturing management team was pleased with its purchase of the Mastercam Swiss component," said Molinar. "We are able to take this intricate little part and machine it all in one operation. Chris promised to stand with us and get us the post. It put out flawless code from start to finish."

"Now that we have a good working post, I can take the code from my computer to the Swiss machine, load it, push the button and have a good part," Molinar continued. "That is how confident I am with the post that Chris from CNC Software has given us."

Eliminating the milling operation and switching to a Swiss machining application yielded big results for the small mud-pump part. Machine time went from a 20-minute, two-operation job to a 6 minute, 10 second, single-machine operation. After running the last 1,000 pieces on the Swiss machine, Ed's Precision Manufacturing was able to save 47 hours for every 200 parts, for a total of 235 hours saved per part run.

"All of that was by eliminating the milling operations," said Molinar. "We essentially eliminated the entire second operation, which was the bulk of the time spent on the mill."

After achieving success with the Mastercam 2021 and Swiss machine application, Ed's Precision Manufacturing is reaching out to find more work that fits its machine parameters. Moreover, with full 5-axis capabilities and a reliable post, the company is revisiting past jobs to determine if those previously performed on a lathe and mill can be produced on the Swiss machine. Besides saving time and money, using the Swiss machine frees up spindle time elsewhere in the shop.

"Not many Texas manufacturers concentrate on Swiss work; a majority of those jobs are being sent to Midwest job shops," said McLaughlin. Ed's Precision Manufacturing hopes to tap into the promising Swiss market share and keep some of those machining jobs in The Lone Star State.

Swiss machining technology may be new to many programmers, but as Molinar learned, it is never too late to master a new skill. A 25-year machinist, Molinar never touched a Swiss machine until recently. Now, he is running them with confidence and achieving great results. He credits the ongoing support from CNC Software and Mastercam Reseller MLC in helping Ed's Precision Manufacturing launch its successful Swiss machining program.

DeCora plans to keep his shop busy with mill-turn and Swiss machining applications. He hopes to further improve manufacturing efficiencies through the addition of collaborative robots, also known as cobots, which are designed to work alongside humans in a shared workspace. By looking to the future, Ed's Precision Manufacturing will continue to provide solutions for its customers.

"We have a lot of customers that give us work on a regular basis," said Molinar. "Some things they want are not in our wheelhouse, but we accommodate them as best we can. Sometimes a job is beyond our capabilities due to sheer size, but for the most part, our customers come back to us because we are able to handle everything that they need."

For more information contact:

Ed's Precision Manufacturing, LLC

6061 Thomas Road

Houston, TX 77041

713-956-1112

sales@edsprecision.com

www.edsprecision.com

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com