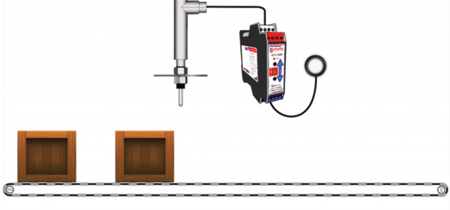

Gauging with a spring loaded LVDT position sensor NewTek NT-GAR-750 Series

NewTek Sensor Solutions offers an extended family of spring-loaded LVDTs for accurate and repeatable dimensional gauging of components as part of manufacturing quality assurance systems. Available in AC- and DC-operated versions, these sensors are used in R&D labs for quality testing, printing operations for roller alignment and automated production lines for dimensional gauging of parts in go/no go inspection. Data collected by NewTek gauging probes are used for online quality control and post-process statistical analysis.

Featuring a stainless steel spring-loaded probe assembly and welded 3/4" diameter hermetically-sealed housing, NewTek Spring-Loaded LVDT Position Sensors are available in ranges from ±0.050" (1.27 mm) to ±2" (50.8 mm). With near-infinite resolution and enhanced repeatability, these gauge heads operate at linearity of ±0.15% over wide operating temperature ranges of -65 °F (-54 °C) to 275 °F (135 °C).

Customized versions of NewTek Spring-Loaded LVDTs operate in higher temperatures up to 400 °F (204 °C) and environments with radiation up to 30MRad. A high-precision gauging probe, available in .315" (8 mm) and .375" (9.5 mm) diameters, is designed to provide reliable performance in measurement ranges from ±.040" (±1.0 mm) to ±0.200" (±5 mm).

NewTek offers its Spring-Loaded LVDTs in AC, DC voltage or 4-20 mA current outputs. The AC-operated LVDT gauge heads are suitable for operation in higher temperatures because the sensor is segregated from the electronic circuitry. While the LVDT works in a hostile environment, a signal conditioner that provides power to the sensor and demodulates output operates remotely in a benign area. NewTek offers its NTC-600 Signal Conditioner for this task. The output is displayed locally or downloaded into a PLC for statistical process control.

Where temperature exposure is not an issue, a DC-operated LVDT gauge head can eliminate the installation and cost of signal conditioning equipment. With electronics built into the assembly, the sensor simplifies mechanical set-up into automated machinery.

NewTek offers both standard off-the-shelf and custom units with a choice of probe contact tips, custom spring rates and an optional pneumatic probe. Visit youtube.com/watch?v=dU4b_fEEI3c to see a demonstration of how NewTek Spring-Loaded LVDTs identify when parts in an automated production line are out of tolerance. Data is sent to a PLC that provides an alarm to operators.

For more information contact:

NewTek Sensor Solutions

7300 US Route 130 North, Bld. #7

Pennsauken, NJ 08110

856-406-6877

sales@newteksensors.com

www.newteksensors.com