Full Range of Workholding Solutions

February 1, 2019

This device is used for grinding the teeth of a gear.

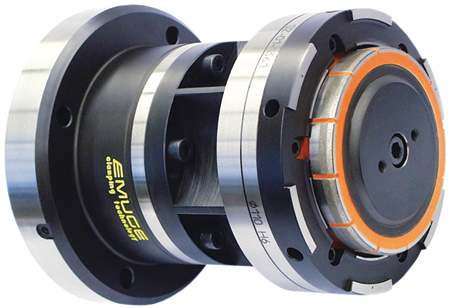

Emuge Corp., a manufacturer of precision workholding devices, offers a comprehensive line of clamping solutions. "Emuge's workholding division specializes in providing accurate, almost maintenance-free customized solutions for applications from low volume job shops to high volume automotive production environments," said an Emuge spokesperson.

"Our workholding group stays close to our customers to learn about their unique challenges and production environments. Doing so helps us develop the best solutions for their applications," said David Jones, Precision Workholding Manager at Emuge Corp.

The precision workholding lineup includes:

- With its expanding-bush design, Emuge's System SG is used in many machining operations such as hobbing, shaping and shaving for gear production, as well as milling and inspection. The System SG's large surface area contact with the workpiece provides a clamping solution that is rigid, accurate and repeatable.

- The high precision System SP is used not only to clamp workpieces but also to clamp tools. By applying an axial force, the clamping sleeves move in the direction of the force and expand radially. This eliminates the clearance between clamping sleeve and body, and between clamping sleeve and workpiece. System SP achieves concentricity of < 0.002 mm (corresponding to < 0.0001").

- For workpieces that have a short clamping base or for diameters with a very large tolerance, System SZ is the best choice. By applying an axial force, a slitted collet is radially expanded by a cone. Simultaneously, an axial movement occurs, clamping the workpiece.

- When the eccentricity between pitch circle and seating bore is very small, diaphragm clamping System SM is ideal. It allows clamping of the gear wheel at the pitch circle for machining the seating bore. The gear wheel is clamped in both axial and radial directions.

For more information contact:

David Jones

Emuge Corporation

1800 Century Drive

West Boylston, MA 01583

800-323-3013

david.jones@emuge.com

www.emuge.com/products/precision-workholding

< back