BeroSim anticipates and avoids possible material deformities in cutting processes.

"BeroSim increases efficiency and enables significant savings on resources," said a Lantek spokesperson.

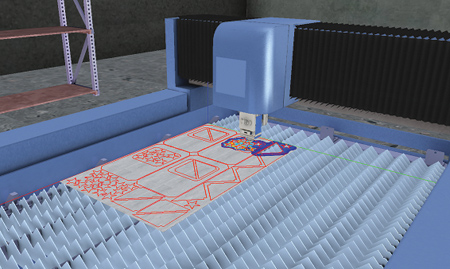

Lantek has launched the BeroSim in collaboration with Vicomtech, the Visual Interaction and Communications Technologies Center Foundation. The BeroSim 3-D simulation software allows users to graphically and interactively calculate how heat sources affect sheet metal in the laser or plasma cutting process. "The BeroSim solution will help the metal and sheet metal industry compete in a global environment driven by Industry 4.0 and advanced manufacturing," said a company spokesperson.

By simulating the sheet metalcutting process, it is possible to anticipate and detect possible unforeseen anomalies in the layout phase. Since the BeroSim program is virtual, testing is not done on the laser or plasma cutting machines. This saves valuable machine time, materials and energy plus minimizes the risk of possible breakdowns or workplace accidents.

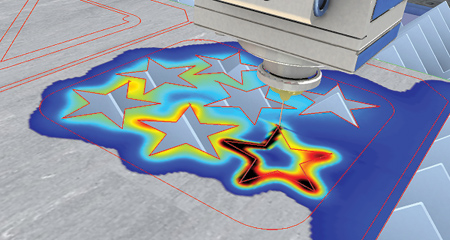

Using plasma or laser technologies increases the overall temperature of the sheet and modifies the properties of the material. These modifications may cause the characteristics of the sheet to become altered. BeroSim simulates heat distribution through the sheet as its cut and demonstrates how the heat affects the material.

BeroSim allows cutting strategy and the definition of cutting and machining order. This prevents possible material deformities. The user can correct the cutting path and trajectory of the machine at any time, maintaining the optimal quality of the sheet.

"Digital transformation has become a key aspect in the industrial sector, which needs advanced technological solutions that provide added value, something that is only possible with research and innovation," explained Dr. Iñigo Barandiaran, Head of Vicomtech's Department of Industry and Advanced Manufacturing. "The industrial sector must continue to be an economic engine and guarantor of stable employment, and this will be achieved with the help of technology."

"With BeroSim, we assist the change process and the modernization of the sheet metal machining, simulation and verification sector," said Susana García, head of CAD/CAM systems development at Lantek. "BeroSim provides a set of innovative capabilities for greater efficiency in production processes, which enables the optimization of both material, human and economic resources."

For more information contact:

Lantek Systems, Inc.

5412 Courseview Drive

Suite 205

Mason, OH 45040

877-805-1028

info.usa@lanteksms.com

www.lanteksms.com