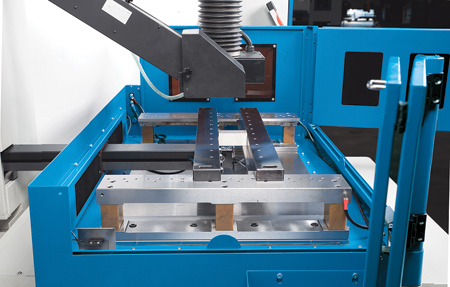

The NeoSpark 500 can be used for workpiece lengths up to 1,200 mm and widths up to 700 mm.

The NeoSpark 500 can be operated via remote control.

The workpiece geometry is programmed via teach-in function to enable a perfect division. This shows a machined construction platform made of stainless steel components.

Markus Schnell, Product Solutions Expert, CES, evaluates the results.

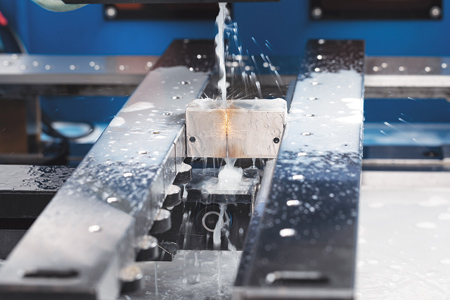

The NeoSpark 500 cuts high-alloyed tool steel.

Continental Engineering Services (CES) is a wholly-owned subsidiary of Continental and develops new solutions for technologically challenging tasks in the specialty fields of automotive interiors, drivetrains and chassis applications. Its operation is focused on driver assistance systems, automotive electronics, electrical drive systems and control systems for conventional drives. The company has 1,500 employees-mostly engineers and technicians-at its German headquarters in Frankfurt/Main and at international sites in Europe, Asia and America.

"Our success lies in the transfer of automotive expertise in a wide variety of applications and industries. As one of the few development service providers, we not only offer consultation and development services, but also have in-house manufacturing capabilities," said Markus Schnell, Product Solutions Expert at CES. This full-service provider not only offers customized developments, but also implements manufacturing, including prototype and small batch productions, at its Continental production site in Karben, Germany.

Complete Solutions for a Clean Cut

"At our Technology Center, we have access to state-of-the-art manufacturing processes and can execute many different process steps in a relatively small space. This benefits the customer in regards to quality, flexibility and speed," Schnell said.

Schnell works in additive design and manufacturing. The team employs additive production, also called 3-D printing, to produce pipes, brake calipers, holders or frames attached to a metal plate, where the metal plate subsequently will have to be separated from the component. Initially, the manufacturing specialists used a saw for this purpose. But they never were truly satisfied with the results, since the cut surfaces never were smooth and had to be reworked. So, the team was looking for a better solution and researched wire electric discharge machines as an option. Schnell described the requirements as "the need for a complete solution and a robust machine that could quickly cut different and also very hard materials, such as aluminum and stainless steel."

Perfectly Cut Solid Materials

A first look at the market indicated that CES would have to make a considerable investment to find a solution for this relatively minor task. "But then we found the KNUTH NeoSpark 500. Contrary to similar products, it could be used for many different materials," Schnell said. "The price-performance ratio was also impressive. Still, we were a bit skeptical, if the machine really would be able to fulfill our needs."

In 3-D printing, it is often necessary to separate solid metal plates with diameters up to 300 mm. "The NeoSpark 500 can be used for workpiece lengths up to 1,200 mm and widths up to 700 mm," explained Patrick Jöhnk, KNUTH Sales Associate. "The machine uses a molybdenum wire that enables it to cut through extremely hard material with ease." The CES engineers were convinced with just one sample cut and placed the order.

Expectations Exceeded

Technicians from both companies worked together to set up the machines in Karben. Schnell said, "Operator training was super as well; the Neo-Spark is surprisingly easy to operate. Both our engineers and our trainees can quickly become familiar with these machines."

The CES operators use the wire EDM about four hours per day and for a much wider scope than initially thought. "The cutting results are great and no rework is required," said Schnell. "Meanwhile, we also use the NeoSpark to cut finished functional parts in small batches."

One of the reasons for the enhanced cutting results is the use of a custom electrolyte that increases the cutting performance and ensures quick removal of the eroded material. "We just recently added this machine to our portfolio, and we will continuously improve it to meet our customers' specific requirements," said Jöhnk.

"For our purposes, one machine at this time is sufficient, but our other manufacturing departments have also shown interest," said Schnell.

Features and benefits of the KNUTH NeoSpark 500 high speed wire EDM:

- Workpiece length x width x thickness (max.): 1,300 mm x 800 mm x 500 mm

- Cutting technology for metal 3-D printing

- Virtually no pressure on the component

- Delicate structures can be machined without the risk of deformation or microcracking in the cut surface.

"The NeoSpark 500 provides a perfect balance between cutting accuracy and high cutting speed," said a KNUTH spokesperson. "It is significantly more cost-efficient than conventional wire EDM, and long wire life means high productivity and minimal downtimes."

For more information contact:

KNUTH Machine Tools USA

590 Bond St.

Lincolnshire, IL 60069

847-415-3333

info@knuth-usa.com

www.knuth-usa.com