Automated Material Processing Using On-board Touchscreen

November 1, 2015

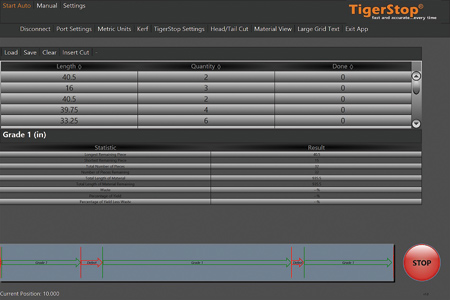

TigerTouch shown on-board the TigerSaw 1000

TigerTouch is equipped with the Microsoft Surface Pro 3 tablet.

TigerTouch has a pleasing and simple visual graphic interface.

Operators can easily see cut list progress.

"TigerStop is now offering TigerTouch, a completely new and innovative software solution for fully automated material processing. Cut-off, punching, boring and machining equipment requiring length measurement can now couple a TigerStop positioning system with TigerTouch, which operates on a touchscreen tablet interface. TigerTouch provides a sophisticated and user-friendly visual representation of the actual material process, allowing for greater control and customization on the manufacturing floor. TigerTouch is equipped with the powerful and easy-to-use Microsoft Surface Pro 3 tablet, with its large, 12 inch touchscreen," said a company spokesperson.

TigerTouch supports both push-feed and set-point cut lists from manual to full-auto processing. The program allows the user to download cut lists straight from the office. TigerTouch can then optimize all the material in the cut list, on the fly, based on the operator's specific needs.

"We designed TigerTouch to dramatically improve operator ease-of-use and allow the user to have everything from manual to full auto processing at their fingertips," said Spencer Dick, Founder and CEO at TigerStop.

TigerTouch combines the following all in one package:

- Optimizer with Dynamic Optimizing

- Allows combination of cut lists

- Supports full label printing for easy identification of parts once they are cut

- Off-the-shelf and customizable Surface Pro 3 touchscreen tablet

- Visual cut lists with up to three grades

- Download a cut list directly to tablet from office PC or USB stick

- Supports manual to fully automatic processing

- Supports automatic pushing of material or simple stop operations

- Leave cut lists, and return later

- Allows changing of the cut list on the fly

- Simple, user-friendly interface.

For more information contact:

TigerStop LLC

12909 NE 95th Street

Vancouver, WA 98682

360-254-0661

www.tigerstop.com

< back