Beyond Drive from Kennametal comes in a range of grades and geometries. All feature a bronze TiOCN top coating.

Advanced technologies, both for Beyond Drive and KM4X spindle connections

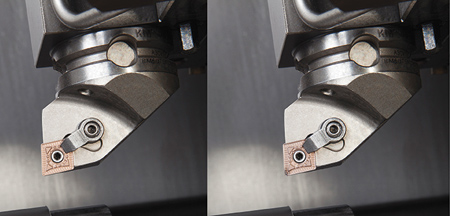

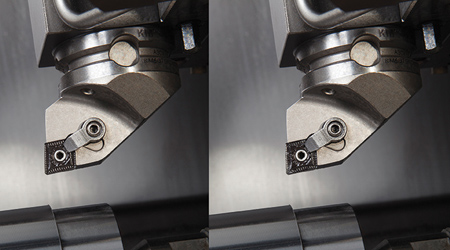

More effective wear identification with Beyond Drive

Beyond Drive makes wear detection easy

On black inserts the wear is extremely difficult to detect. As a result machine operators often exchange the insert before it reaches the end of tool life to ensure process safety.

"With significantly longer tool life and improved edge utilization in field tests, Kennametal's newly launched Beyond Drive portfolio of cutting inserts are being called the new gold standard for turning. Adding a new titanium oxy-carbonitride outer coating (TiOCN) not only increases wear- and abrasion-resistance for lower temperatures and longer tool life, its bronze color is an effective wear indicator as opposed to black-surfaced inserts. Where inserts had been thrown away early in favor of safety because of poor wear identification, operators are now reporting notably longer service life per edge, even in aggressive environments. Depending on the application, field tests are showing up to 30% more parts per edge," said a company spokesperson.

Beyond Drive is an entire portfolio of new grades and geometries that emphasize ease of selection and use across work materials and turning conditions. Specific customer demands addressed by Beyond Drive include reduction of notch wear in demanding applications and reduction of crater wear in difficult materials, all while improving wear identification.

Beyond Drive is specifically designed for providing improved performance and longer life in many critical turning tasks across steels, stainless steels, cast irons and high-temperature alloys.

The Beyond Drive MR (medium roughing) insert has a high positive rake angle that works with the smoothly curved cutting edge to reduce cutting forces.

"Indexable double-sided inserts are subject to high cutting forces, and are commonly seen as less stable. MR's rake profile without the points of load concentration results in a stable insert body, despite the high positive rake. Even with high depth-of-cut applications, turning processes are safer and more stable, ensuring lower load on the machine tool and workpiece. Additionally, MR inserts also feature formed-in coolant channels that deliver flood coolant efficiently to the cutting edge," said the spokesperson.

Kennametal's KM4X spindle connection adds increased stability to Beyond Drive's design. Sizing the right spindle connection with the right machine tool helps optimize the productivity of the entire system.

"Another advantage is running dry, where Beyond Drive performs very well. Even in very aggressive turning environments involving external scale or heavy, interrupted cuts, Beyond Drive is showing increased performance," said a spokesperson.

For example, in one test for a plant producing cast-iron transmission components, with no change in feed, spindle speed, or depth of cut, Beyond Drive completed 325 pieces per cutting edge compared to 200 pieces for the plant's current inserts. Not only was this an increase in parts per edge, projected machine hours freed per year totaled 125 while the number of inserts required per year dropped from 813 to 500.

For more information contact:

Kennametal Inc.

1600 Technology Way

P.O. Box 231

Latrobe, PA 15650

724-539-5000

www.kennametal.com