Automation Cell on a rail system consisting of a dynamic robot serving multiple Sodick EDM machines. The cell is controlled by custom software that scheduled EDM jobs, allowing for high capacity operation.

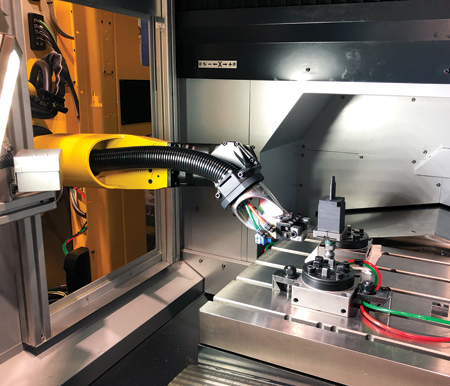

A 6-axis robot serves a Sodick High Speed Mill and EDM duo. This automation system loads and unloads electrodes and the workpiece. The 6-axis robot allows for flexibility, magazine arrangement and custom gripping tools.

Sodick, a provider of EDM technologies, has expanded its services with the launch of a new Automation division. "Building on its reputation for advancing the manufacturing industry through purpose-driven innovation, Sodick looks to refine the process further with the expansion of its automation systems for die-sinker and wire-cut EDMs," said a company spokesperson.

"Advancement means going beyond our machines and looking to improve the entire process," said Marius Onica, Product Solutions Manager. "We are excited to expand how automation can work in manufacturing and EDM, and this new division will allow us to bring some exciting systems into shops around the world."

"For many manufacturers, EDM is the preferred solution for achieving complex shapes with high level of accuracy," said the spokesperson. "The addition of robots, handling systems and sensors provide real-time feedback, greater repeatability and improved quality. As the demand grows within the industry, Sodick answered the call for customized solutions, providing automation for both new and older machines."

The addition of robotics to die-sinker and wire-cut EDMs creates a standardized, qualified process that allows continuous automatic operation with high-precision and high-speed machining, removing human error and workload.

"We are incredibly excited to connect more machines for our customers," said Marius. "It is the next step in achieving a higher level of precision and stability in the shops."

The new automation division will operate out of Sodick's North American headquarters in Schaumburg, IL, providing custom robotics and software for their full range of EDMs and tooling systems.

For more information contact:

Marius Onica

Sodick Inc.

601 Commerce Drive

Schaumburg, IL 60173

847-310-9000

monica@sodick.com

www.sodick.com