Albion produces historical re-creations of popular medieval swords along with other sword designs.

Since implementing HCL CAMWorks Professional software, Albion's sword production time has been cut from a week to a single day.

With the new processes from CAMWorks, Albion Swords has been able to introduce new sword models significantly faster.

A North American manufacturer of metal swords and sword re-creations was looking for a way to speed up its machining and cutting process, which relied on older drawings that could not handle more complex 4-axis machining. Albion Swords Ltd. needed a program that could support complex machining while integrating with SOLIDWORKS.

Founded in 1999 by Howard and Amy Waddell as Albion Armorers, the company began producing its own sword product lines in 2001. Although a relative newcomer to the sword manufacturing market, Albion quickly established itself as a high-end standard for exacting historical re-creations of popular medieval and other sword designs.

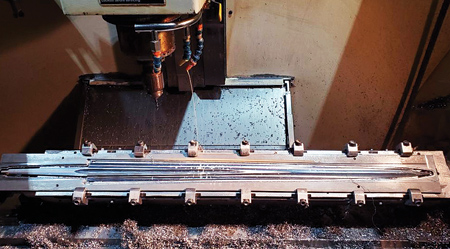

The blades are machined from 1075 carbon steel blanks. "Before I joined the company in 2016, sword drawings were created using CAD software, as were the toolpath programs used to cut the blanks," said Mark Risley, Designer and Programmer at Albion. "Not only was the process slow and inefficient, but it also hit a wall when we began developing more complex sword designs that required 4-axis machining. We were beginning to develop new products that required milling laterally, vertically and with twists. We started looking for a better method for producing blanks to improve productivity and increase throughput."

According to Risley, Albion Swords was initially interested in the SOLIDWORKS 3D design package for developing new sword product designs, but was pleased to discover that SOLIDWORKS serves as the modeler for all CAMWorks solutions, including CAMWorks Professional multiaxis milling software, which supports 3- and 4-axis milling.

"We learned that CAMWorks is nested inside SOLIDWORKS software as a plug-in, which would enable us to model a sword blank and export the G-code for milling in one step," said Risley. "We realized that the seamless nature of the CAMWorks and SOLIDWORKS integration would transform a lengthy, labor-intensive approach into a process that is almost effortless by comparison."

Since implementing CAMWorks Professional multiaxis milling software, Albion Swords has realized substantial productivity gains. For example, with the previous manual process and CAD system, it took about one week to model a sword blank, generate a toolpath and cut the sword blank. With CAMWorks software, Albion can model, program and cut a sword blank in a single day.

This improvement in efficiency is helping the company energize its new product development effort.

"We recently introduced five new sword models that were developed, manufactured, tested and released in record time," Risley said. "With our previous process, introducing five new products would have taken three or four years. With CAMWorks, we were able to cut that down to six months."

In addition to enabling what Risley describes as a "considerably more rapid process," the move to CAMWorks software is helping Albion Swords maintain consistently high levels of quality while simultaneously cutting scrap and waste by 75%. Risley attributes the quality improvements and reduction in waste to the ability to simulate tooling runs with CAMWorks Virtual Machine, which simulates toolpaths and tooling operations using the G-code generated for each specific machine.

"Instead of relying on dry runs and creating a greater volume of scrap whenever there were issues, we now simulate all of our toolpaths in the CAMWorks virtual 3D environment," Risley said. "Before we cut a sword blank, I run the simulation program to check on things like tool deflection or potentially problematic features. When it comes to toolpaths, there are a lot of nuances that you want to first identify in the software instead of blowing your tools up later on. CAMWorks enables us to do that and improve quality while we boost productivity overall."

Albion Swords has also leveraged CAMWorks tools to further automate its processes. The company tapped the flexibility of the SOLIDWORKS and CAMWorks Application Programming Interface (API) to create its own CAM post editor, which allows the company to configure each post to meet the company's specific milling needs and further automate its processes. With this tool, Albion can edit the post to change the initial set-up of a part program or change how particular operations work, such as having one post for standard jobs and another for 4-axis runs.

"I typically start with the strategy recommended by CAMWorks, and then I may edit that strategy with our post editor based on the simulation output," Risley said. "This enables us to break the G-code down into blocks to fit different needs, which makes cleaning up the code effortless. There is also an incredible amount of etching and runes on our blades, and CAMWorks automates that process as well."

Albion works closely with leading swordsmiths and historians when designing and creating its swords. To signify its commitment to quality, the company etches The Albion Mark on every product that it makes. Each mark corresponds to an Albion product line that is defined by unique aesthetic and functional qualities. The swords are finished and assembled by hand.

"In recent years, we have experienced increasing demand for our swords," Risley concluded. "The automated tools in CAMWorks are helping us meet that demand."

For more information contact:

Albion Swords Ltd.

888-806-4356

www.albion-swords.com

HCL Americas

15974 N. 77th Street #103

Scottsdale, AZ 85260

480-367-0132

inquiries@camworks.com

www.camworks.com