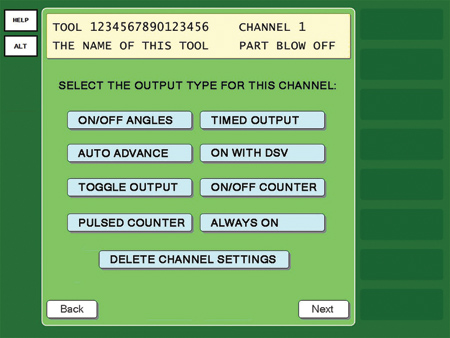

New ProCamPAC PRO Cam Output Menu showing new cam types.

Wintriss Controls Group has announced a new ProCamPAC PRO Programmable Limit Switch (PLS) for its flagship SmartPAC PRO Press Automation Controller. Building on the ProCamPAC PLS, the new "PRO" PLS features five additional cam timing options that provide increased flexibility and functionality.

A new Toggle Cam Output performs an asymmetrical toggle function, turning an output off or on for different stroke amounts. The output can be used to operate diverter gates and to control complex gagging operations. The new On/Off Counter Cam Output precisely controls functions that need to operate at a preset interval instead of on every machine cycle. Operating similarly, a new Pulsed Counter Cam Output is programmed with an "on angle" and a dwell time instead of an on-off output.

Useful when running configurable tooling, a new Channel Always On Cam Output will simply turn on and stay on until a new tool is loaded. ProCamPAC PRO PLS also features a Triggered Cam Output that actuates a precision one-time cam timing signal based on a preset trigger, such as an external input from ancillary equipment, an extended period of machine idle time or a job change. This output type is suitable for diverting parts during a warm-up period, QC checks or when bad parts are determined by an outside measuring system.

SmartPAC PRO

The Wintriss SmartPAC PRO press automation control integrates programmable limit switch, die protection, clutch/brake control, tonnage signature analysis and automated set-up of counterbalance and shut height into one control.

Its built-in Ethernet capability allows for viewing the press status and other information from networked controls located anywhere. Requirements include a remote network connection and a web browser. The SmartPAC PRO Info Center feature allows users to display set-up sheets, part drawings and other information right at the press.

SmartPAC PRO architecture supports advanced connectivity features, such as remote access from PCs and mobile devices, email messaging and compatibility with the Wintriss IIoT production tracking OEE ShopFloorConnect software solution.

The SmartPAC PRO enclosure is also available with an optional Industrial Pendant Arm for mounting on presses. Wintriss also offers stand-alone die protection, sensors, connection hardware and tonnage monitoring systems.

For more information contact:

Wintriss Controls Group

100 Discovery Way, Unit 110

Acton, MA 01720

800-586-TECH

www.wintriss.com

www.shopfloorconnect.com