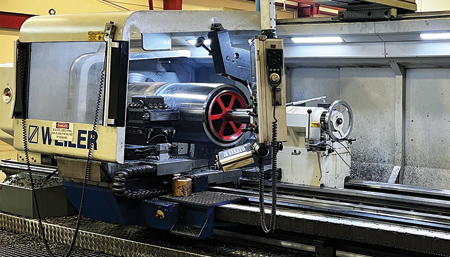

TAM International has expanded capacity with the addition of Weiler lathes.

With the Weiler V 110, a 4-way precision lathe with automated cycles, TAM International is able to machine larger workpieces it previously outsourced.

TAM International manufactures down-hole oilfield products on its Weiler lathes.

TAM International has relied on manual machines to produce its portfolio of down-hole oilfield products, but there came a point when repairing older machines no longer made fiscal or operational sense. It was time to invest and upgrade. The challenge was implementing new machines without redesigning the entire manufacturing process.

"For manual machinists, moving over to programming is a big transition," said Mark Newman, Vice President of Global Manufacturing. "For this reason, traditional CNC machines were ruled out."

Newman researched solutions and soon discovered the Weiler E 90 lathe, a straightforward machine with the features needed to manufacture TAM's products, which include components for workover operations, casings and inflatable and swellable packers.

"Weiler lathes put greater control and versatility in operators' hands than manual lathes," said a Methods Machine Tools spokesperson. Methods began representing select Weiler products in North America earlier this year. "Weiler lathes have the flexibility to run manually or can be programmed on the user-friendly control. Weiler developed the option specifically for shops like TAM-those that want the best of manual machines and the programmability of modern CNC machines."

The E 90 is a cycle-controlled precision lathe that features an easy-to-use conversational control that enables a user to program a complex machining process without knowing a single line of M- or G-code. An operator enters basic information, such as the tool, direction of the cut, type of machining and depth of cut. The control allows the intuitive creation of a number of cycles that are then stored in the controller to be called up at the touch of a button. These can then be run individually or as part of an automated sequence. The benefit to the user is shorter programming times and efficient one-off and small batch production.

To unlock their full capabilities, TAM turned to its Weiler dealer, Koch Machine Tool (now part of Methods), for applications support and training. Johnny LeFlore, a former Koch employee and now Methods' Weiler Product Manager, had created a manual for Weiler customers that was developed into a training curriculum and technical training manual. By the time it got to Newman and TAM international, it was an integral learning asset for the team.

Newman said that switching from their older manual machines to the E 90 instantly improved TAM's operations. Cuts were more rigid, and the machine removed greater amounts of material in less time. And because the machine has high quality finishing capabilities, TAM was able to eliminate hand-polishing, a costly secondary operation.

Specifications of the E 90 include:

- Distance between centers: 78.7"/590.6" (2,000 mm to 15,000 mm)

- Swing over bed: 35.4" (900 mm)

- Swing over cross slide: 20.9" (530 mm)

- Cross slide travel: 23.2" (590 mm)

- Width of bed: 23.6" (600 mm).

TAM was soon ready to add to its machining capacity and made the decision to take on larger workpieces that they had historically outsourced. The company collaborated with its machine tool dealer and ordered a Weiler V 110, a 4-way precision lathe with automated cycles. TAM could now machine large-diameter workpieces without an oversized spindle hole.

"This investment decreased cycle time compared to older machines, lowered production costs and put more control in the hands of our machinists," said Newman. "I cannot say enough about the V 110's versatility. We are able to machine 85% to 90% of the material all from one end," Newman said. "Its capacity for boring and turning are hands-down better than any slant bed lathe I have ever owned."

Specifications of the V 110 include:

- Distance between centers: 118" to 472.5" (3,000 mm to 12,000 mm)

- Swing over bed: 45.7" (1,160 mm)

- Swing over cross slide: 31.9" (810 mm)

- Cross slide travel: 22.8" (580 mm)

- Width of bed: 35.4" (900 mm).

For more information contact:

TAM International

4620 Southerland Road

Houston, TX 77092

800-462-7617

info@tamintl.com

www.tamintl.com

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

877-MMT-4CNC (877-668-4262)

www.methodsmachine.com