Weighing just under 10 lbs., the MagicCleaner 150 is a lightweight tool for portable use.

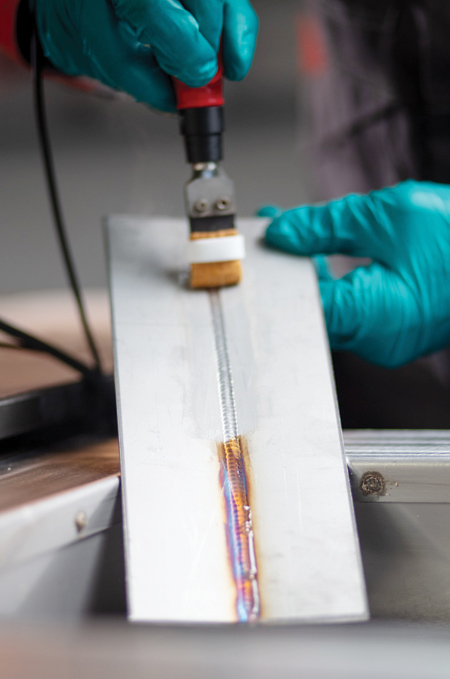

Before and after comparison: The TIG weld seam is electro-chemically cleaned quickly and easily. The cleaning pad is automatically supplied with electrolyte fluid.

Black or white print for permanent marking of stainless steel workpieces eliminates the need for embossing, engraving or gluing.

The MagicCleaner is available in two sizes: MagicCleaner 150 for flexible and portable use and the MagicCleaner 300 for more intensive use on long welds.

The newest generation of Fronius MagicCleaner is available in two models. This advanced electro-chemical cleaner is designed to provide a high quality finish on stainless steel TIG welds and surfaces, helping welders meet high standards of aesthetics and hygiene. The machine can also mark workpieces with logos or serial numbers.

"Strong temper colors in TIG welds can interfere with a clean visual appearance," said a company spokesperson. "Discoloration can range from being a mere visual distraction to a quality defect to be avoided at all costs. The colors indicate the chromium oxide protective layer is not intact, which can be a starting point for corrosion or deposits."

The MagicCleaner restores the protective layer over welds and stainless steel surfaces; it cleans and passivates workpieces in a single step. At just under 10 lbs., the lightweight MagicCleaner 150 (15 A output) is portable.

The larger MagicCleaner 300 is suited for more intense applications and for cleaning longer TIG welds. Delivering up to 30 A of performance, the MagicCleaner 300 weighs about 30 lbs., with a 1.8l cleaning fluid tank and patented compressed air blower. Both versions are easy to operate and supply the cleaning pad with electrolyte. This eliminates the need for dipping into open containers of cleaning fluid.

With the MagicCleaner, the electrolyte solution is delivered precisely where it is needed. The included pads and brushes penetrate into corners and gaps, providing optimal cleaning with minimal use of materials.

"Electro-chemical cleaning is more resource-efficient than conventional pickling in chemical baths and does not attack the material, as sandblasting does," said the spokesperson. "Fronius also uses innovative inverter technology, making the devices lightweight and energy efficient."

"On highly polished materials, weld seams should not just be clean-they should really shine," continued the spokesperson. "Achieving this could not be easier with the electro-chemical polishing function. Direct current (DC) is used to quickly brighten seams and make them shine."

Company logos, item or serial numbers and barcodes can be applied to stainless steel in black or white print. All that is needed is a suitably designed film and a special electrolyte solution. This is a cost-saving alternative to embossing, printing or gluing.

For more information contact:

Fronius USA LLC

6797 Fronius Drive

Portage, IN 46368

219-734-5500

sales.usa@fronius.com

www.fronius.us