Inserts with New Geometries for Grooving and Parting Off

November 1, 2021

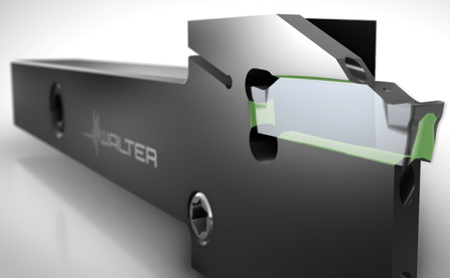

Walter Cut DX18 insert in grooving toolholder system.

The Walter Cut DX18 double-edged grooving and parting off inserts with insert widths of 0.059" to 0.157" (1.5 mm to 4 mm) are the latest addition to Walter's grooving product range. The patent pending cutting insert is seated in the insert pocket with a prismatic design.

"This insert seating substantially eliminates the tendency for vibrations, increasing insert life as well as toolholder life," said a company spokesperson. "The design also prevents incorrect engagement, especially for narrow insert widths, and enables high indexing accuracy. Elevated protective edge is an inbuilt feature of these DX18 carbide inserts that protects the clamping finger of the toolholder from chip-wash and acts as an additional chip breaker-further enhancing tool life and process reliability."

New DX18 geometries include the "C" cut off geometries CF6, CF5 and CE4 for cut off (parting off); "G" grooving geometries GD6 and GD3 for grooving; and "U" universal geometries UF4, UD4 and UA4 for groove turning, parting off and grooving. The UD4 acts as a trouble shooter to achieve enhanced chip control. The new "R" full-radius geometries for copy turning and radius grooving include the sintered RF7.

The holders for these inserts are made for Swiss-style machines as well as conventional lathe and bar feeder machines. The holders are offered in both precision-cooling through-coolant configuration as well as external coolant configuration for economies. The G4014-P holders are uniquely designed for Swiss machines, allowing inserts to be indexed while on the machine gang tooling, reducing insert indexing time by as much as 70%. The G4011 holders are offered for conventional lathes in both square shank and Capto style designs, while the G4041 blade style holders are suited for parting off close to shoulders in a limited space.

For more information contact:

Walter USA LLC

N22 W23977 RidgeView Pkwy West

Suite 100

Waukesha, WI 53188

800-945-5554

www.walter-tools.com/us

< back