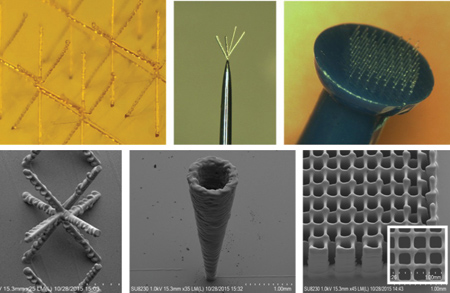

Examples of Aerosol Jet 3D printed micro-structures

Optomec has received new patents covering the use of Aerosol Jet for producing 3D micro-structures. This novel capability enables the production of miniature elements with a resolution down to 15 micron features-approximately 1/5 the width of a human hair and smaller than the resolution of the human eye. The capability has been demonstrated for a range of materials, including polymers, metals and composite structures.

These new grants are the latest in an IP portfolio that totals more than 75 patents issued, with global protection including the U.S. and key markets across Asia and Europe.

The new 3D micro-printing patents present a method for fabricating 3D structures using in-situ heating or UV illumination to modify the properties of aerosol droplets as they are jetted onto a target surface. In the case of the UV embodiment, light at least partially cures photopolymer droplets, or alternatively causes droplets of solvent-based nanoparticle dispersions to rapidly dry in-flight, and the resulting increased viscosity of the aerosol droplets facilitates the formation of free-standing 3D shapes. Lateral resolutions of 15 um have been achieved, with layer thicknesses of 100 nanometers and aspect ratios of >100X for structure heights measured in millimeters.

Dr. Michael Renn, Chief Technology Officer, is the inventor on these new patents, and has more than 50 patents to his credit in total. "Optomec continues to invest heavily in its core technology, seeking to extend the already broad range of applications for its Aerosol Jet solution" said Dr. Renn, "The capability demonstrated with our 3D printed micro-structures work is already seeing potential applications in semiconductor packaging and medical device markets."

Optomec Facility Recertified for ISO 9001

Optomec Inc. has also announced that its Clover, SC, production facility has been recertified for ISO 9001 for the 8th consecutive term. The Clover site has now maintained its ISO 9001 certification for more than 20 years. ISO 9001 is a key element of Optomec's Quality Management System, delivering added assurance to its production customers in a wide range of industries including the energy, industrial, aviation, health care, electronics and research markets.

"The ISO 9001 certification process is a fantastic tool that engrains the concept of continuous improvement throughout the organization," said Doug Childers, General Manager of Optomec's Clover, SC, facility. "It drives every one of our employees to solve small problems early, rather than go around big problems later."

For more information contact:

Optomec

3911 Singer NE

Albuquerque, NM 87109

505-761-8250

sales@optomec.com

www.optomec.com

Optomec

1050 Huffman Way

Clover, SC 29710-1400

803-222-4561