Aerospace Fastener Hole Drilling and Countersinking in One Step

November 1, 2021

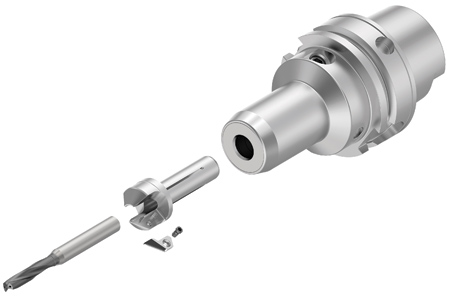

Kennametal's HiPACS is an easy to assemble system comprised of three components: a reducer sleeve, countersinking insert and solid carbide drill. The system works with any standard hydraulic chuck.

HiPACS system utilizes standard PCD-tipped or diamond coated solid carbide drills.

Kennametal has introduced the HiPACS drilling and countersinking system for aerospace fastener holes. Designed to drill and chamfer holes in one operation, the high-precision tool is engineered to meet the aerospace industry's stringent accuracy requirements while delivering increased tool life in machining composite, titanium and aluminum aircraft skins.

"Most fastener hole tools used today are complex made-to-order tools with long lead times," said Georg Roth, Product Manager, Kennametal. "HiPACS uses standard, off-the-shelf components for quick delivery and low cost per hole, by allowing the drill and chamfer insert to be indexed independently from one another. It is the only indexable drilling and countersinking system on the market that can hold the aerospace industry's required fastener hole chamfer tolerances in just one operation."

Designed to be clamped in a standard hydraulic chuck, the HiPACS modular system consists of three components:

- A reducer sleeve with a built-in high-precision pocket seat: In conjunction with a standard hydraulic chuck, this component is designed to provide secure clamping and a runout of no more than 3 µm, increasing tool life and hole quality.

- A PCD countersinking insert: This is intended to eliminate the need for expensive custom solution step drills, reducing manufacturing costs while meeting the industry's accuracy requirements.

- The two series of solid carbide drills: The drills-both diamond-coated and PCD-tipped-cover all material combinations found in a typical aerospace assembly. The straight shanked tools allow for length adjustments in increments of 10 mm.

"The HiPACS drilling and countersinking system can be utilized on all machines typically used for aerospace applications," said a company spokesperson. "In less stable applications, such as robot end effectors, the diamond coated carbide drills offer excellent tool life and hole quality. PCD-tipped drills excel in stable conditions such as gantry machines.

"With an industry standard interface, HiPACS can be utilized on any CNC machine, and is suitable for a variety of drilling and countersinking applications."

For more information contact:

Kennametal Inc.

525 William Penn Place

Suite 3300

Pittsburgh, PA 15219

800-446-7738

www.kennametal.com

< back