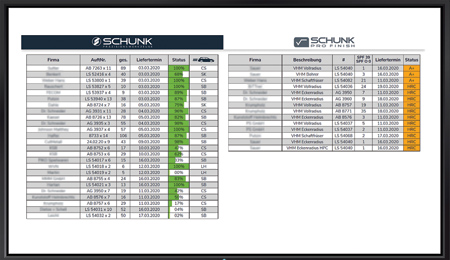

Schunk uses a digital scheduling board to monitor multiple regrinding jobs.

Mixed batch tools are sorted as required for production rather than by customer orders.

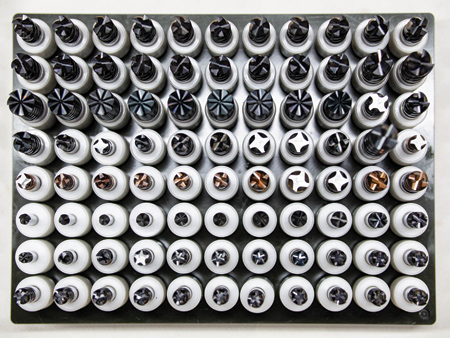

Tools can be sorted by diameter and tool type.

Christian Schunk and the ANCA MX7 tool grinding machine with RFID workflow.

Schunk utilizes ANCA RFID tool carriers for chaotic regrinding of mixed customer batches.

Schunk Präzisionswerkzeuge GmbH, founded in 1979 by Siegfried Schunk, started off in a garage in Coburg, Germany. From its humble beginnings, the former resharpening service has transformed into a solution provider that manufactures its own precision cutting tools as well as customized tools for special applications. This former one-man company has consistently grown and employs today 15 highly qualified employees.

Managing Director Christian Schunk began manufacturing cutting tools in 2010 and continues to grow this segment. The turnover of new tools is now 60% of the business and supplies the automotive, aerospace, die-mold and medical industries. In addition, Schunk offers a professional resharpening service. This includes edge preparation and re-coating at its own coating facility-SCHUNK pro finish. The coating service was introduced by Christian Schunk in 2009.

The company provides regular customer contact and individual service and aims to simplify customer processes by facilitating their tool management. Customers like that they not only buy the tools from Schunk, but also get complete tool management: regrinding, edge preparation and even coating.

Pioneer of Loading Mixed Tool Batches

Schunk invested as early as 1998 in a 5-axis CNC tool and cutter grinder and developed its own chaotic loading system for mixed batches. Founder Siegfried Schunk implemented a chaotic regrinding system for mixed customer batches using Manutec Siemens robots on three different grinding machines.

Regrinding with mixed batches of tools has been practiced at Schunk for more than 20 years, and the employees are familiar with the flexibility of the chaotic system. For the owners, being able to grind a mixed batch of tools unattended translates into increased productivity. This "industrial" way of thinking was the main driver for investing in an ANCA MX7 in 2017. Schunk is now investing in a second ANCA MX7, expanding the existing RFID workflow.

For Christian Schunk it was important to retain the chaotic loading capability and at the same time benefit from the increased accuracy of collet changing.

Digital Workflow in Combination with Schunk Service-Box and Storage System

To structure the chaos of mixed tool batches and multiple jobs, Christian Schunk has developed his own storage system to sort all tools of a customer order on a common tool board. The board has a label and a barcode containing all relevant job information such as tool type, number of tools, due date and other relevant data, and serves to re-collect the tools after grinding for each customer order.

Schunk has not only implemented the ANCA RFID workflow for chaotic resharpening, but also uses the production data in a digital scheduling board showing the status for each job ticket.

Running Grinding Machines Unattended Increases Productivity

Schunk Präzisionswerkzeuge has reduced costs and increased operational efficiency by using ANCA's RFID technology. The system allows tools to be sorted as required for production rather than by customer orders.

Any number and combination of tools from different customers can be prepared for regrinding at a dedicated programming station. Every tool gets assessed at the station. Skilled operators then select and modify the required grinding program. The individual program is then coded onto a RFID toolholder and subsequently the toolholder and tool will be placed in a pallet for the grinding machine. Every RFID toolholder receives the customer name and job number, so it is easy to find the original customer order after grinding.

Upon the return of the tools after regrinding, the RFID information gets read out and the tool will be returned to its original customer order. The RFID toolholder goes back into storage and can be used for another job in the future.

In production, the RFID information is scanned and the tool grind file is loaded; all grinding parameters, required wheel pack changes or collet size changes are executed automatically.

Christian Schunk explained: "It makes sense to keep collet changes at a minimum, which means tools usually get sorted by diameter and tool type, like square endmills, ballnose endmills or drills. This way we are not only optimizing cycle times, but also extending the life of collets, and we save the collet adapter. Most importantly, it contributes to a better runout."

Christian Schunk also makes sure the machines are utilized at a maximum, therefore the employees will start on Thursday to prepare tools for automated regrinding on the unstaffed weekend. The tool pallets are loaded to suit the optimal production processes. Using chaotic loading increases productivity and minimizes cycle times.

Chaotic loading is a proven formula for efficiency. Schunk previously worked as per customer order, loading all diameters of one customer together. Now they have changed to a fully chaotic loading system, independent from the actual customer order.

For the delivery of the second ANCA MX7, Schunk and ANCA are working on an expanded RFID workflow that will accommodate a larger tool diameter of 25 mm.

How Does ANCA's Loadermate and RFID Solution Work?

Andreas Sommer, ANCA Product Manager, explained: "ANCA offers a variety of automated regrinding solutions for mixed batches-such as collet loading with Nikken collets-which means that the tool and collet are getting changed together, as per the FX5 with the AR300 robot. The Loadermate allocation sets up a mixed batch of tools for unmanned operation."

Alternatively, ANCA offers collet changing and RFID on the MX platform. "ANCA's Dynamic Tool Group Manager software is at the heart of the RFID workflow. It can group tools by tool type, required regrinding operations and infeeds based on the wear factor, or assign an individual tool file to one tool only," continued Sommer. "With RFID, the required information is recorded at the programming station and the tool is coupled with the RFID tag. The machine picks up the tool together with the RFID toolholder. It then scans the RFID and automatically calls up the grinding program, sets all grinding parameters and loads the correct wheel pack. If a collet change is required, the machine will execute the collet change automatically. The RFID is parked at an interchange station while the tool gets loaded and reground."

"The ANCA RFID solution means customers can chaotically load tools into a loader pallet by creating an individual program for each tool," added Sommer. "The tool position inside the pallet can be swapped with another tool anytime if a tool needs to be resharpened in a hurry. The tool and cutter grinder can run the regrinding operation individually and unattended. The duration of unattended machine usage depends on the type of loader and the capacity of pallets."

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

For more information contact:

ANCA Inc.

31129 Century Drive

Wixom, MI 48393

248-926-4466

usainfo@anca.com

www.anca.com