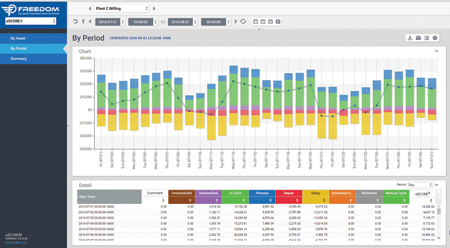

Freedom's e$CORE module translates data collected into dollars and effectively monetizes gains and losses based on user-defined parameters.

"Freedom IOT brings productivity improvement to any shop floor with its comprehensive Smart Manufacturing Platform that seamlessly connects all industrial assets and business systems and provides real-time data collection and monitoring," said a Freedom IOT spokesperson. "The Freedom Platform connects and collects data from any industrial asset, regardless of brand, age or process and reports are accessed anytime, anywhere via browser devices, including desktops, laptops, tablets or smart phones. This Cloud-enabled IoT platform includes customizable dashboards and alerts and helps identify manufacturing bottlenecks and inefficiencies and streamlines manufacturing processes."

"Our Freedom Platforms provide the operational intelligence our customers need to increase efficiency, overall equipment effectiveness (OEE) and profitability," said Jeff Price, Executive Vice President of Freedom IOT. "Machine tool technology is advancing rapidly and we make the complex matter of properly identifying inefficiencies very fast and simple. Real-time production monitoring arms production teams with the data required to optimize utilization, improve quality, root out inefficiencies and maximize profit."

The Freedom Platform is available at three plan levels to right-size the program to individual shop and process needs. Plans include Light, Pro and Premium.

The Light Plan includes Freedom's eLOG module that provides machine or machine group filtering, configurable date/time ranges, flexible shift scheduling, machine strip chart, metrics reports and machine alert pareto charts. eLOG Cloud-based software suite is the heart of the Freedom platform, as it seamlessly connects and collects production asset data. Notifications are sent via email under the Light Plan.

The Pro plan includes all of the features of the Light Plan along with auto part counting, OEE metrics, downtime event analytics, part production reports, program analytics, production category reports and tool reports. It also includes text message alerts and a factory income statement function from Freedom's e$CORE financial module. e$CORE translates the data collected into dollars and monetizes gains and losses based on user-defined parameters.

The Premium Plan includes all components of the Light and Pro plans with the addition of sensor data items, shift reports, real-time dashboards, slideshows and extended data modules for sensor analytics. Additionally, notifications can be set for condition-based triggers.

All plans include Freedom-developed MTConnect adaptors used to connect to CNCs, PLCs and robots, among others.

"IT integration is easy and installation is minimally invasive, completed in a matter of hours. It requires no PLC ladder or NC program modifications and is easy to maintain," said the spokesperson. For assets with industrial controllers that do not support open architecture, Freedom offers a DIN-rail mounted hosting appliance.

For more information contact:

Freedom IOT LLC

4270 Ivy Pointe Boulevard

Suite 240

Cincinnati, OH 45245

513-719-1600

www.freedomiot.com