Grooving System for Heavy-Duty Machining

November 1, 2020

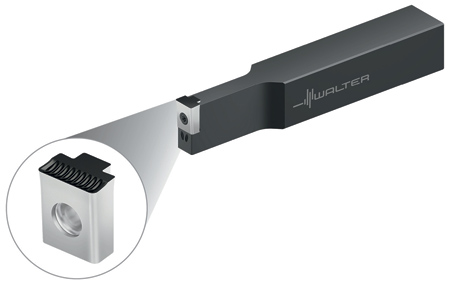

Walter Cut UX grooving system

Walter has introduced the Walter Cut G2016-P/UX grooving system. "This productive and economical system delivers stable and reliable performance in heavy machining and features high feedrates of 0.008 in. to 0.024 in. (0.2 mm to 0.6 mm). The system maximizes tool uptime with its simple-to-operate tangential clamping mechanism for fast replacement of cutting edges," said a company spokesperson.

A tangentially mounted grooving insert with an enhanced seating surface provides increased stability. The insert and pocket design features an axial key stop for added stability against the side cutting (axial) forces. Precision cooling on the flank surface is offered as a standard feature for longer tool life. The chip breaker for the inserts is developed for heavy-duty machining to ensure short chips when cutting at maximum depth and when widening the grooves.

The tangentially mounted inserts, with widths of 0.472" and 0.748" (12 mm and 19 mm), provide stability and feature shank sizes of 25 mm x 25 mm and 32 mm x 32 mm.

The Walter Cut UX grooving system is designed for applications in the energy industry, wind power, shipbuilding as well as general heavy-duty machining.

For more information contact:

Walter USA LLC

N22 W23977 RidgeView Pkwy West

Suite 100

Waukesha, WI 53188

800-945-5554

www.walter-tools.com/us

< back