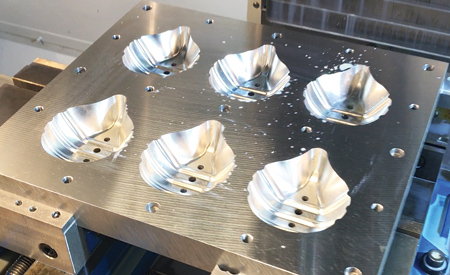

A molding cavity for N95 masks that was machined on a Haas VF-2SS.

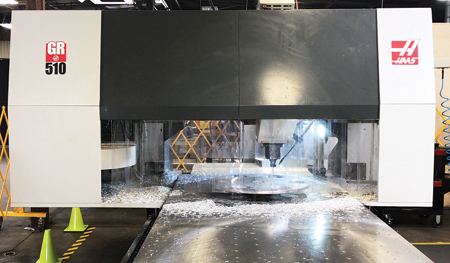

The GR-510 is utilized to machine, drill and tap large Blanchard-ground plates and aluminum dial plates that are used for the mask machine tabletops.

N95 Mask Machines in final assembly at Craig Machine & Design in Louisville, KY.

During the early onset of the coronavirus pandemic, Louisville based Craig Machinery & Design Inc. was tapped to design and build N95 Mask Making Machines to help address the worldwide shortage for Personal Protective Equipment (PPE). According to owner Craig Rabeneck, this project was the most important they have ever taken on.

Each N95 Mask Making Machine was designed and engineered to produce 12 masks per minute. The machine ultrasonically welds layers of a mask together and forms a mold shaped for a close facial fit. As Rabeneck explained, "Basically, the machines are taking plastic, and heating it and welding it together using vibrations to take on the form of a N95 mask. As masks are removed from the machine, the only remaining step is to attach straps."

Craig Machinery & Design is a full-service automation company that designs and builds custom machines for welding plastics, including ultrasonic and vibration welding. Craig Machinery has been using Haas CNC machines to make its products since 2001, when the company purchased its first Haas VF-2SS. Today, the company has five Haas machines: two VF-2SS Super-Speed VMCs, two VM-3 Mold Making VMCs and a GR-510 Gantry Router.

The most recent addition to Craig Machinery's shop is a Haas VM-3 Mold Making Machine that was purchased in March. Delivery of this machine was expedited by Haas and the local Haas Factory Outlet-Midwest after Craig Machinery received the order to design and build three N95 Mask Making Machines. The order quickly grew from three to more than 75 machines as the virus began to surge.

"This was an `all hands on deck' order for us at HFO/Midwest," stated Dave Tucker, President of Haas Factory Outlet, A Division of Midwest Manufacturing Resources. "Craig Machinery provided us with government documents, which we immediately shared with the factory in California to expedite the order at a time when many companies were being asked to shut down. The day the VM-3 arrived at Craig Machinery, we had service engineers in place to make sure it was installed and making chips the very same day."

"The VM-3 arrived at the perfect time to help expedite the N95 Mask Machine order," said Rabeneck. "With the help of the VM-3, we were able to design, build and ship the first three Mask Making Machines in less than three weeks. Typically, a project like this can take up to 14 weeks."

One of the major components produced on the Haas VMCs at Craig Machine are mold cavities. A mold cavity is machined from a solid piece of 6061-T6 Aluminum 60 HRB (Rockwell B) using SGS Ski-Carb square and ball endmills. The toolpath tolerance required is set to .0001" with cusp height <.0001 and can take up to 12 hours, including roughing, 3D rouging and fine 3D roughing.

The company's Haas GR-510 gantry machine also played a critical role in the N95 Mask Machine production. Craig Machinery utilized the GR-510 to machine, drill and tap large Blanchard-ground plates and aluminum dial plates that are used for the machine tabletops. In the past, this process was done using a magnetic drill, but it took hours and was not always accurate. Before 3D CAD, the company would lay out all the parts and use a transfer punch to mark the hole locations on the tops. Now, the ground plates are loaded on the GR-510, and the machine completes the drilling, tapping and other machining in less than an hour.

Craig Machinery & Design founder Ken Rabeneck's passion for tooling and machine design led him to leave his 10-year job at Branson Ultrasonics, which partnered with Craig Machinery on the N95 mask project, to start his own company. In 1977, Craig Machinery & Design was officially founded in Louisville, KY.

Craig Rabeneck officially joined the company in 1989, after completing his master's degree in engineering at University of Louisville. Craig took over Craig Machinery after Ken's retirement, and his two sons have since joined the business. Craig Machinery's industry experience with ultrasonic welding fixtures means it has the knowledge and ability required for making part molds and custom urethane fixtures for a variety of applications.

Haas Factory Outlet, a Division of Midwest Manufacturing Resources, Inc. is the exclusive full-service distributor for Haas CNC Machine Tools and Accessories, supporting the manufacturing communities of Kentucky, Ohio and West Virginia.

For more information contact:

Craig Machinery & Design, Inc.

629 West Magnolia Ave.

Louisville, KY 40208

502-635-7950

info@craigmachinery.com

www.craigmachinery.com

Haas Automation, Inc.

2800 Sturgis Road

Oxnard, CA 93030

800-331-6746

www.HaasCNC.com

HFO Midwest-A Div. of

Midwest Mfg. Resources Inc.

1993 Case Pkwy. N.

Twinsburg, OH 44087

800-833-0246

www.hfomidwest.com