The design features of POW-R-FEED M934 keep chips clear of the cutting zone for free-cutting, clog-free work.

POW-R-FEED M934 four-flute end mills are versatile, doing the easy legacy tasks most four-flute cutters can perform, in addition to extremely aggressive cuts, the company reported.

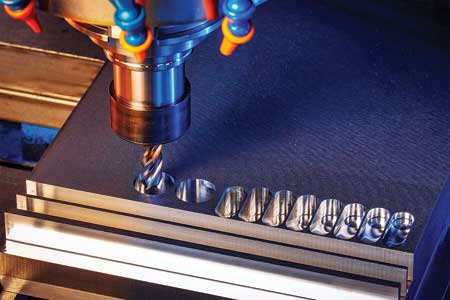

This multifaceted "pyramid" piece in titanium 6AL 4V was cut with a POW-R-FEED M934 four-flute end mill. The M934 performed helical entry, peripheral roughing, facing and milling.

POW-R-FEED M934 end mills are able to make plunge entry cuts cleanly-instead of helical entry-resulting in cuts in cycle time.

IMCO Carbide Tool recently announced development of a new versatile cutting tool. POW-R-FEED M934 4-flute end mills cut aggressive tool paths in a wide range of materials machine shops use most: steel (all types), titanium, plastics, brass, bronze and even aluminum.

"This new extension of the POW-R-FEED M9 series actually exceeded our expectations," said Matt Osburn, Vice President, Technical Director for IMCO. "These new M934 cutters not only prevent chip clogging, which cuts a lot of downtime, but they are also superior to other 4-flutes at ramping and helical entry. They are incredibly versatile at performing any operation for a 4-fluter, and they get higher performance from machining centers to maximize output, regardless of horsepower."

A company spokesperson said, "While M934 cutters easily tackle any operation any legacy 4-flute mill can, they also can perform the aggressive cuts and complex moves legacy 4-flute cutters cannot. Also effective in HEM tool paths, M934 cutters ensure smooth, clog-free operation in 3- to 5-axis machines. So, whatever you need from a 4-flute end mill, M934 cutters can do it at faster feedrates, reduced cycle times and greater profits.

"With popular 20 horsepower 40 taper machines, the M934 cutter actually maximizes the machines' output," explained Steve Avers, IMCO's Technical Support Manager. "One of the best things about these cutters is the free-cutting action. This keeps the cutter turning at high speed and the chips flying. This design eliminates cutting zone barriers to higher productivity, so machines can run at higher speeds, crank out more parts and produce to its upper capacity limits. Aggressive flute and end-face geometries and an exclusive super-slick AlTiSN coating work as a system to keep those chips moving. So, you get higher feeds and metal removal rates and better output all shift, all day."

POW-R-FEED M934 cutters' flute and core designs also open the door for aggressive tool paths, stepovers and depths. The core is carbide with a business end that offers fine cutting edges with high strength plus a wiper flat end for smooth floor finishes. All edges are prepped for long life.

POW-R-FEED M934 end mills are the latest extension of IMCO's POW-R-FEED M9 line of workhorse cutting tools.

For more information contact:

IMCO Carbide Tool Inc.

28170 Cedar Park Blvd.

Perrysburg, OH 43551

800-765-4626

support@imcousa.com

www.imcousa.com