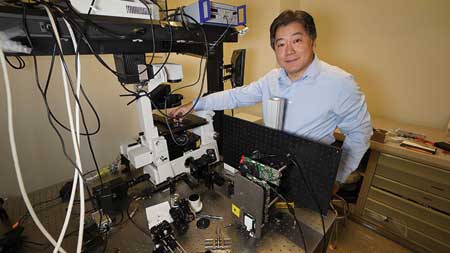

Liang Pan leads a team of Purdue University researchers whose 3D printing innovation produces a higher throughput of high-resolution 3D nanostructures faster and less expensively than traditional laser-based printing technologies. (Purdue University photo/Jared Pike)

Researchers in Purdue University's College of Engineering have developed patent-pending single-photon 3D nanoprinting technology. It produces a higher throughput of complex, high-resolution nanostructures faster and less expensively than traditional laser-based 3D additive nanoprinting technologies, Purdue reported.

Liang Pan, Professor of Mechanical Engineering, leads the team developing the technology that allows 3D nanoprinting at lower laser intensities without the need for femtosecond lasers. It does not rely on single-point scanning processes and therefore produces high-speed and high-resolution results.

"The technology uses less expensive light sources as simple as a laser pointer, which can reduce the tool cost by 10 to 100 times," Pan said. "The writing speed is a few orders of magnitude faster for each beam, and we can further expand to parallel scan with tens to hundreds of beams."

The single-photon technology has applications in nanotechnology research and industry, manufacturing processes and health care.

Pan disclosed the 3D nanoprinting technology to the Purdue Innovates Office of Technology Commercialization, which has applied for patents to protect the intellectual property. Industry partners interested in developing or commercializing it should contact Parag Vasekar, Business Development and Licensing Manager, at psvasekar@prf.org about track code 69873.

Drawbacks of Traditional Nanoprinting

Femtosecond laser two-photon polymerization is widely used for 3D nanostructure fabrication.

"However, this technique is expensive and slow, which presents significant obstacles for commercial use in manufacturing," Pan said. "Alternative options have been developed to increase speed and reduce cost, but they deliver limited resolution and require high-power lasers, unlike our innovation."

Validating the Purdue Method

Pan's single photon-based method uses fast panel writing to construct high-volume and complex nanostructures for wide ranges of use. Notable applications include nanolithography, zero-stiffness microstructures and thermal interface structures.

"We have demonstrated the method by printing 120-nanometer-resolution structures using a low-cost diode laser," Pan said. "We also demonstrated parallel nanoprinting using a nine-by-nine array laser beam."

The next steps to develop the technology are further increasing the scanning throughput and reducing the tool cost. Pan and his team are applying for federal funds for research and development.

The National Science Foundation awarded Pan two grants to conduct his research.

For more information contact:

Purdue Research Foundation

1281 Win Hentschel Blvd.

Suite 2500

West Lafayette, IN 47906

765-588-3470

www.prf.org