Automated High Precision Plasma System

April 1, 2024

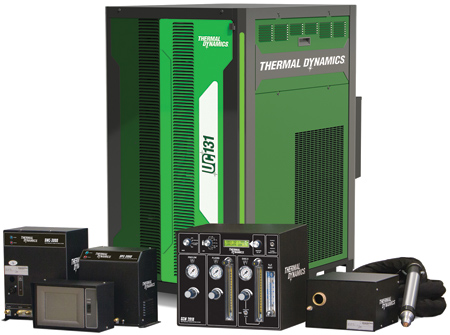

Thermal Dynamics UC Series of high-precision automated plasma sources features a modernized inverter block and new cabinet design.

Thermal Dynamics Automation's UC Series of high-precision automated plasma power supplies features four models offering cutting power ranging from 130 up to 800 amps for maximum productivity, cut quality and reliability for piercing mild steel up to 50 mm (90 mm edge start) and stainless steel up to 100 mm (160 mm edge start).

"The UC series delivers development work from the last two years to cut faster, better and smarter," said Dirk Ott, VP-Global Plasma Automation, Thermal Dynamics. "For example, two UC 201, UC 301 or UC 401 can now be connected double cutting output to 400, 600 or 800 amps, respectively, or they can operate independently. Furthermore, the QuickPierce technology improves very thick mild steel cutting performance, making the new UC series the ideal choice for heavy duty applications."

Target applications for the paralleling capability include fabricators and steel service centers that use two torches on the same gantry and want to increase cutting speeds on steel plates up to 2" (50 mm) thick. It also lets fabricators cut stainless steel and aluminum sections up to 6.25" (160 mm) for applications in the power generation, pressure vessel, windmills, chemical and petrochemical processing industries. To double a torch's cutting output, users need to change the SpeedLok consumables cartridge, which takes less than a minute.

The UC systems are equipped with a modernized inverter block with high quality power switching components for fine control of the cutting process and reliability, an LED strip for an at-a-glance assessment of machine status and an optional WiFi communication for Industry 4.0 (IoT) applications.

Features include:

- Bevel wear parts. The consumables cartridges are now all the same length for easier set-up when bevel cutting. Users can cut bevel angles up to 45° on material thickness from 1/4" to 2" (6 to 50 mm) on mild steel and up to 4" (100 mm) on stainless steel.

- New bevel angle data makes it easier to program CNCs to cut the following bevel angles: V bevel top, Y bevel top, X bevel, V bevel bottom, Y bevel bottom and K bevel.

- Complete set of parts for underwater cutting, which reduces smoke and glare to create better working environment.

- Improved XT torch head design provides accurate parts alignment for better tolerances.

- QuickPierce consumables offer outstanding 300A and 400A piercing and parts life performance, reducing piercing time by up to 40% on mild steel thicknesses ranging from 1" to 2" (25 to 50 mm).

- EtherCat (optional) and wireless connection capabilities Industry 4.0-ready. EtherCat delivers faster connection to a CNC for uploading and downloading data. The TD 4.0 App (available for IOS and Android) devices offers full process setting and troubleshooting support and makes retrofits and robotic installations easier.

For more information contact:

Thermal Dynamics

82 Benning Street

West Lebanon, NH 03784

866-279-2628

www.thermal-dynamics.com

< back